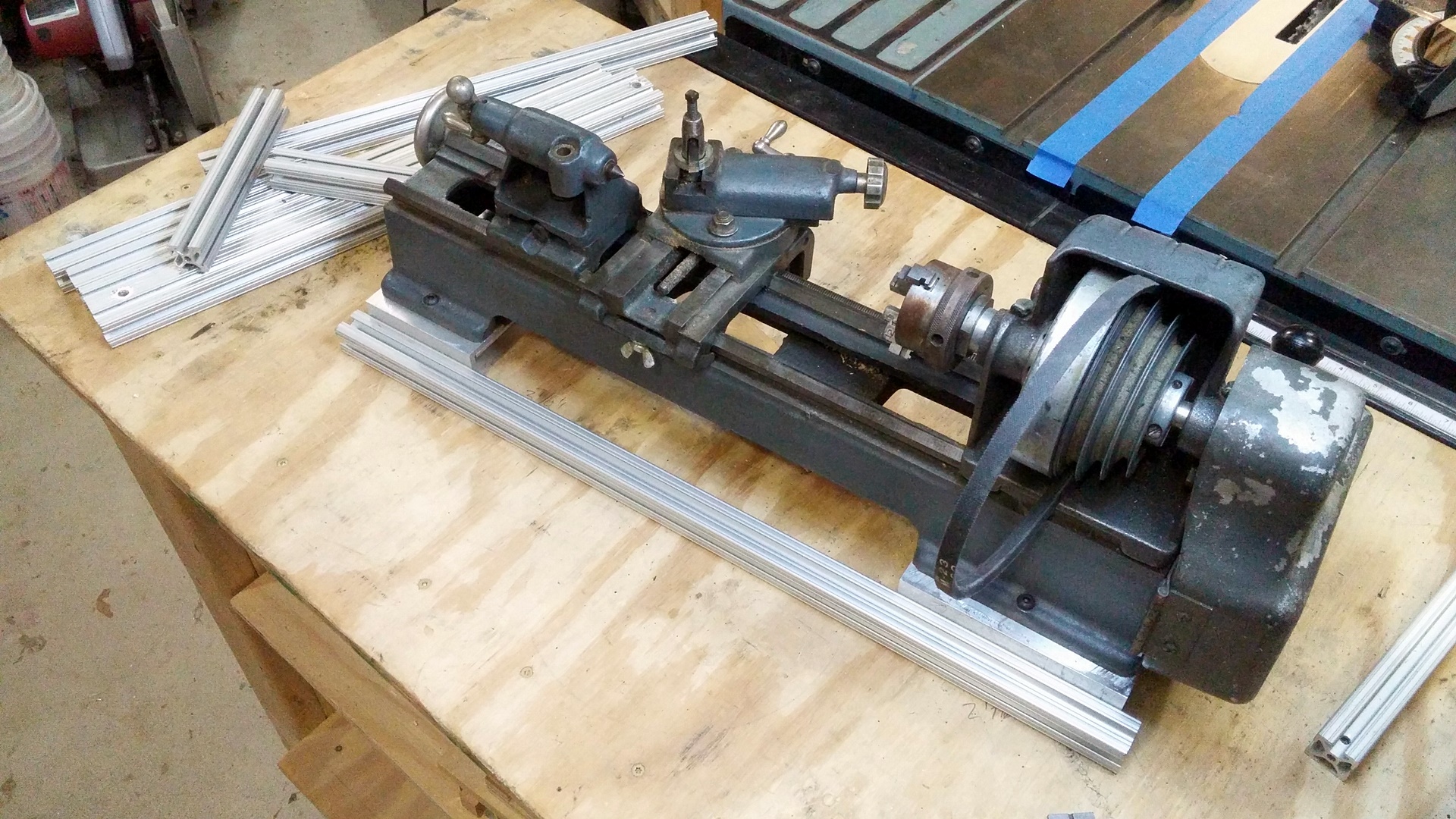

Motor Mount for a 70y.o. lathe

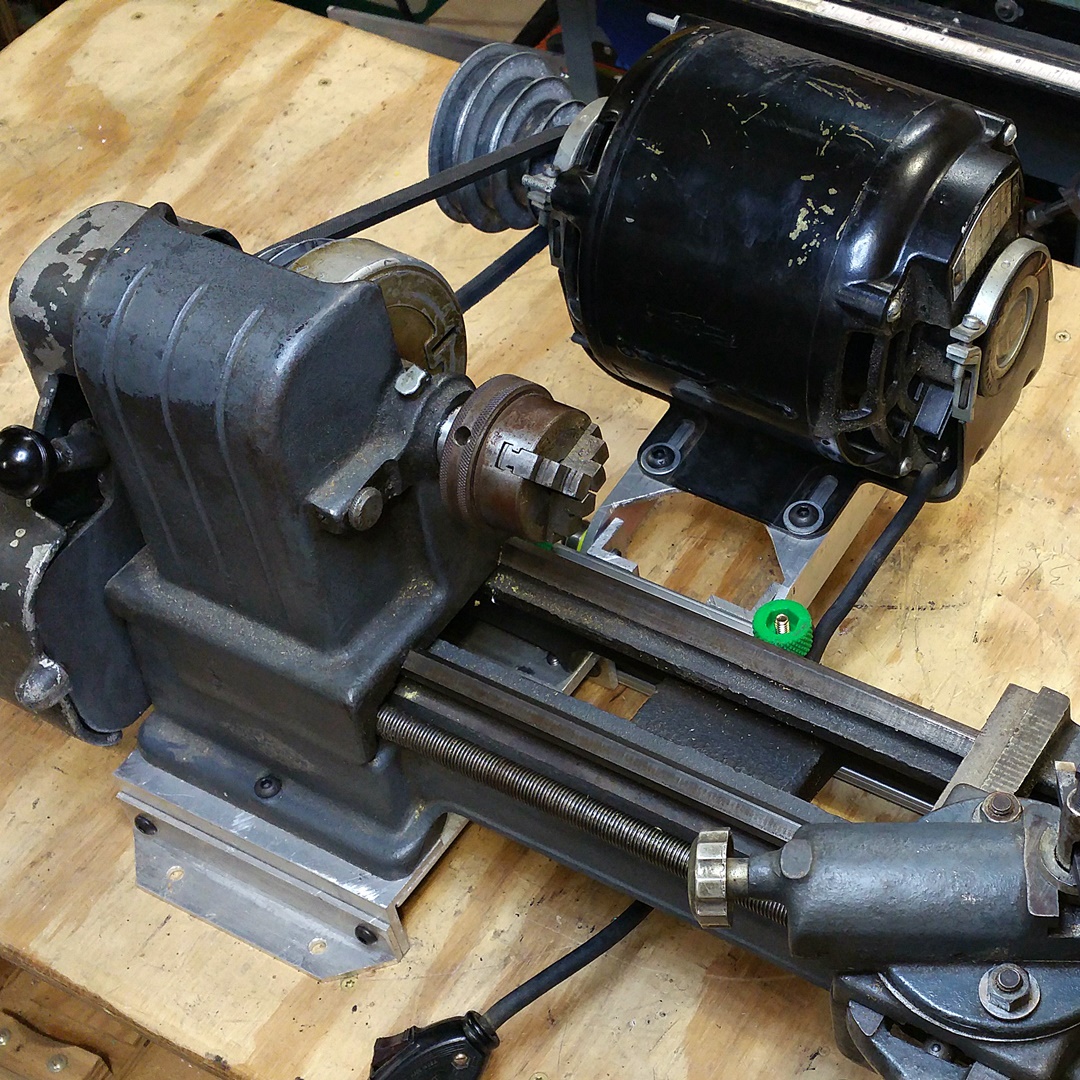

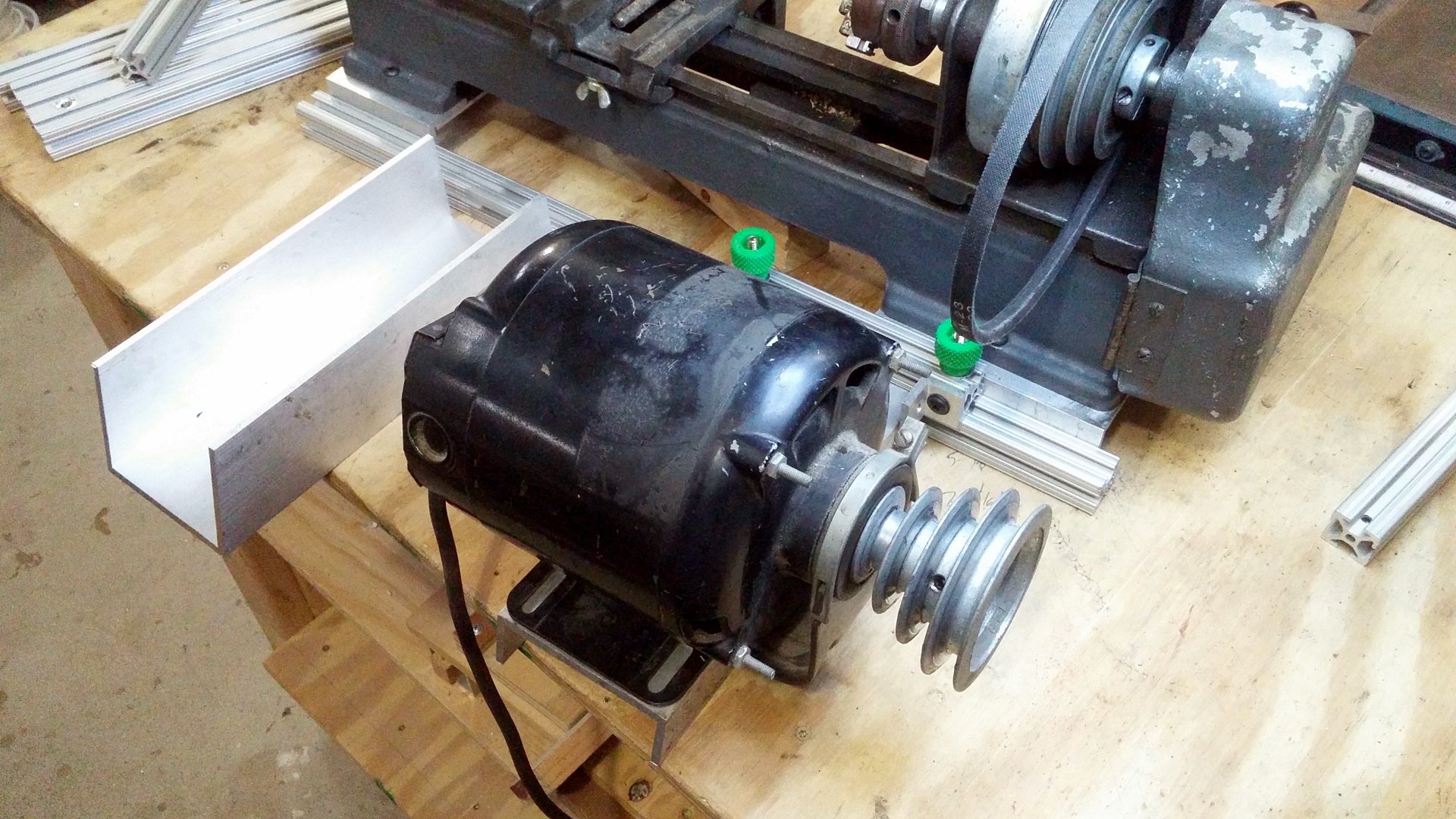

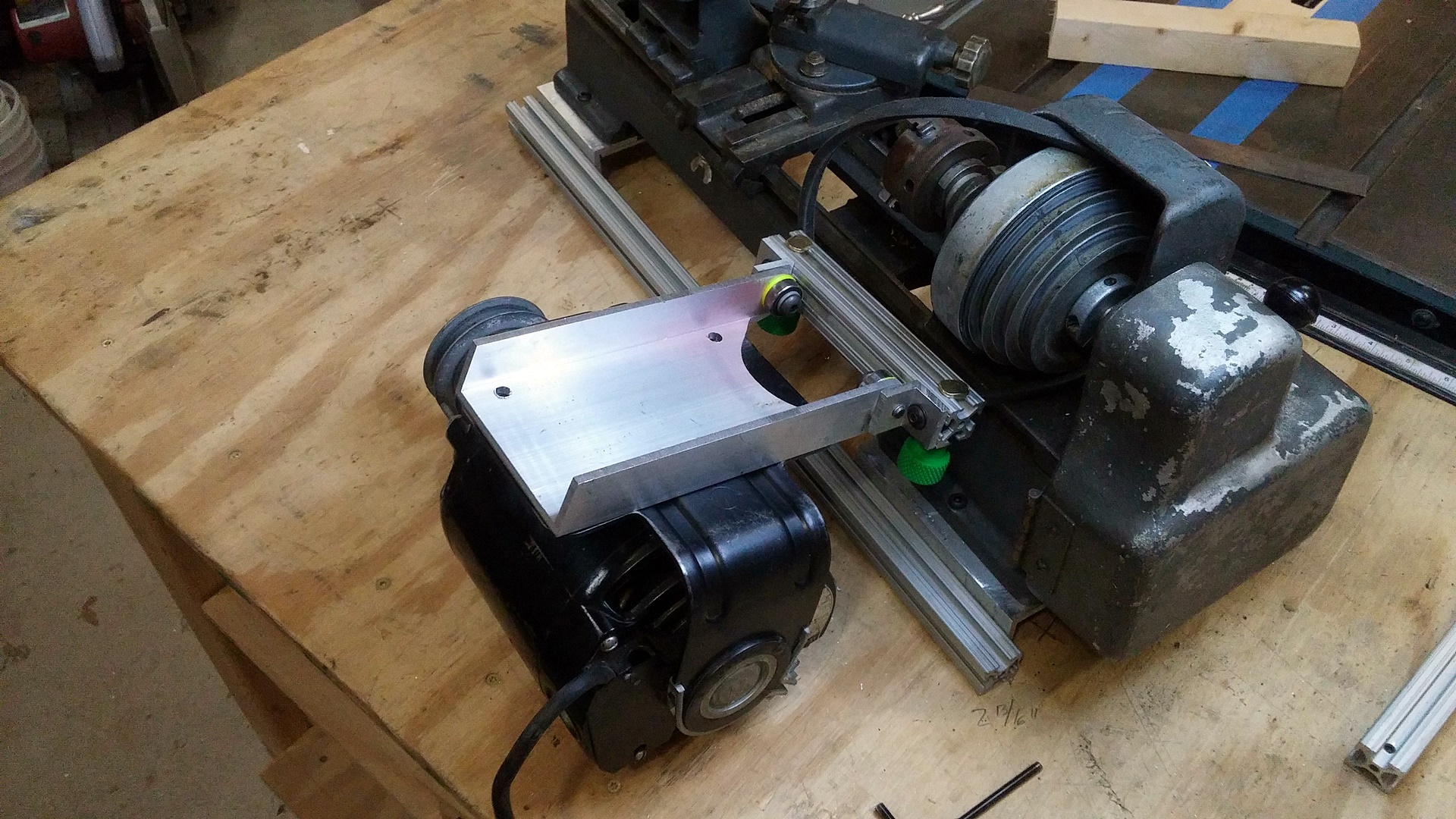

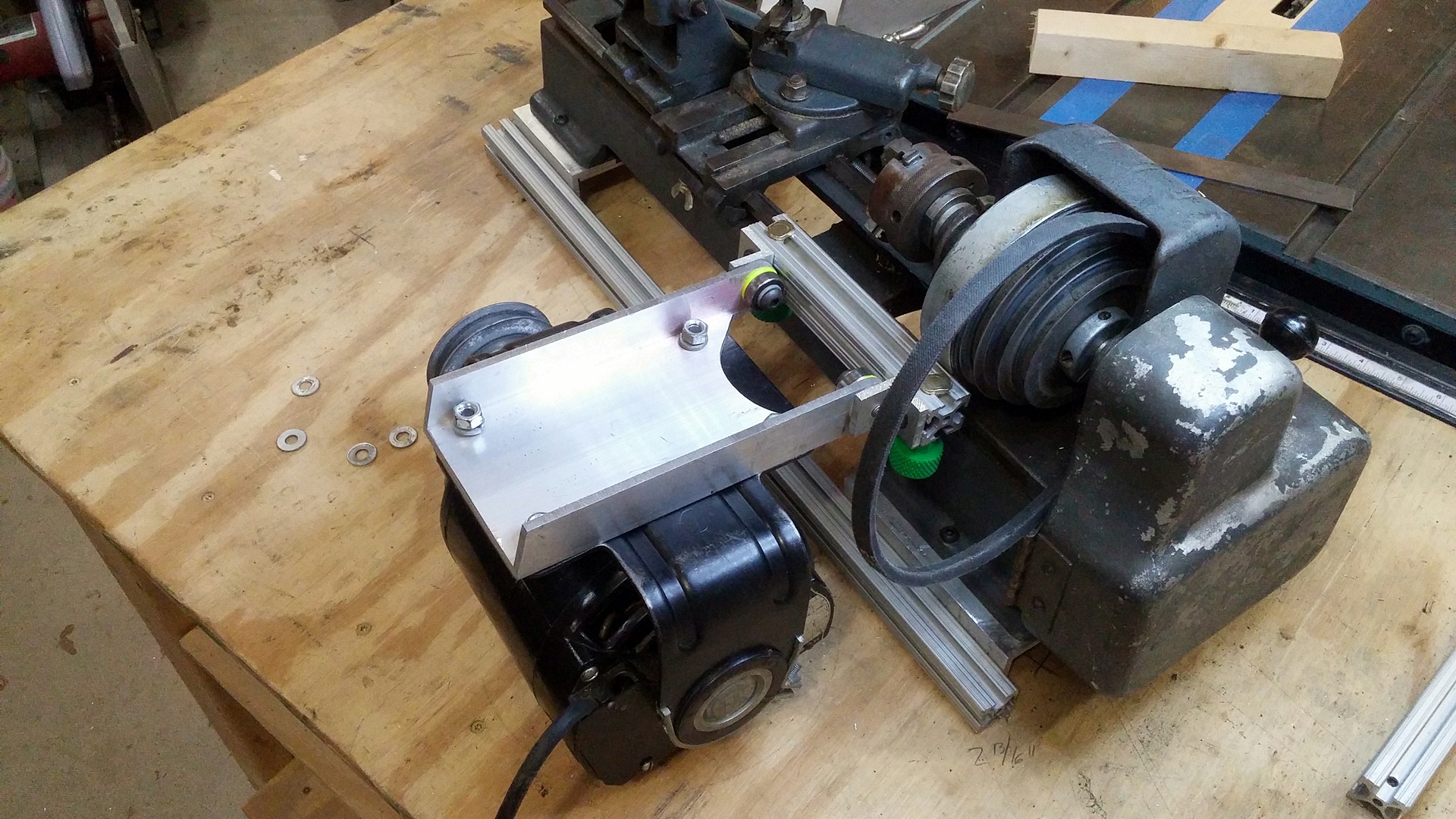

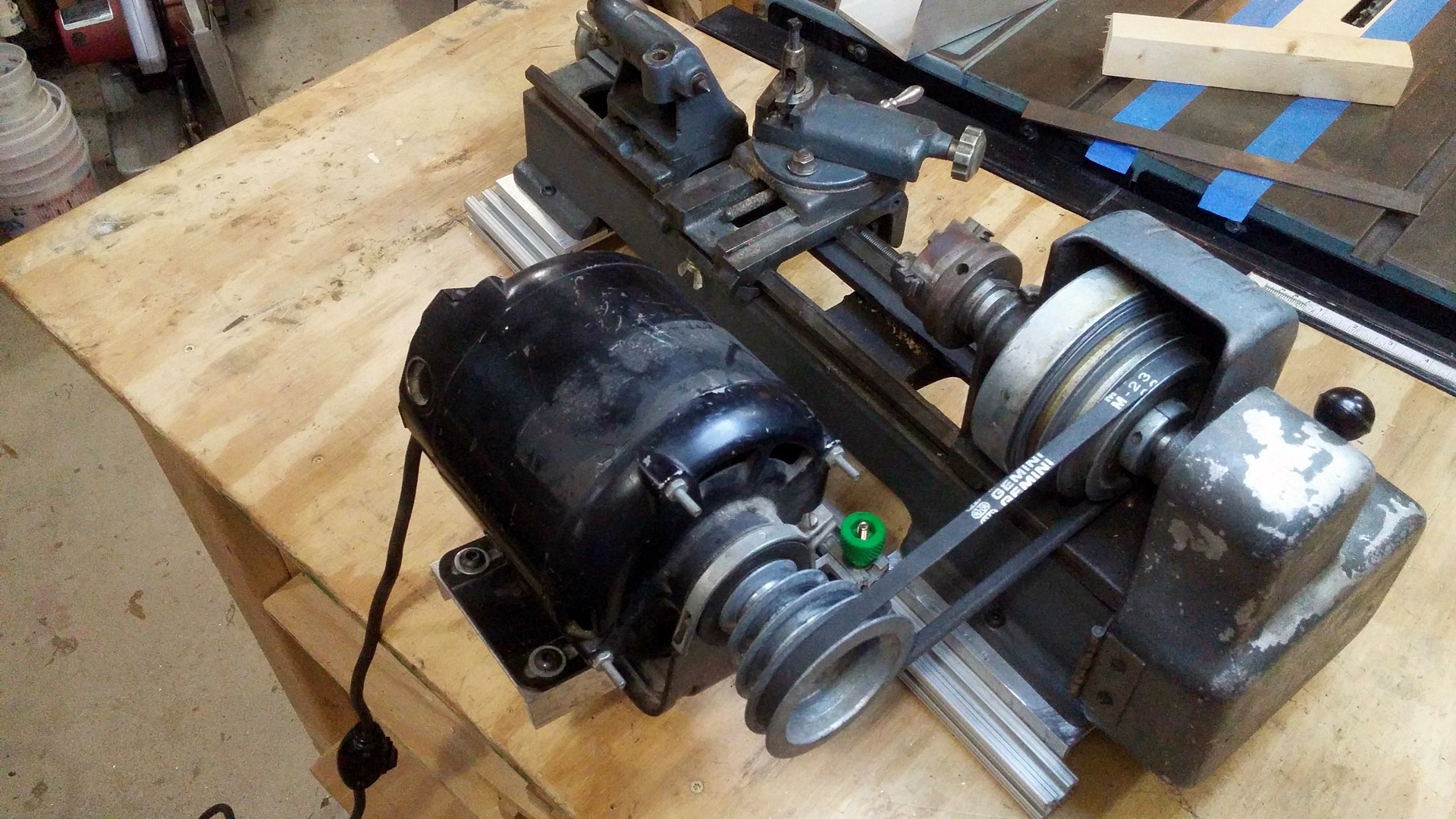

I have a small Craftsman 109.20630 metal Lathe from approx. 1948 which was missing a motor and motor mount. I salvaged this motor and pulley from a drill press. I wanted a tool-less method to tension the belt and adjust the motor left and right for different speeds.

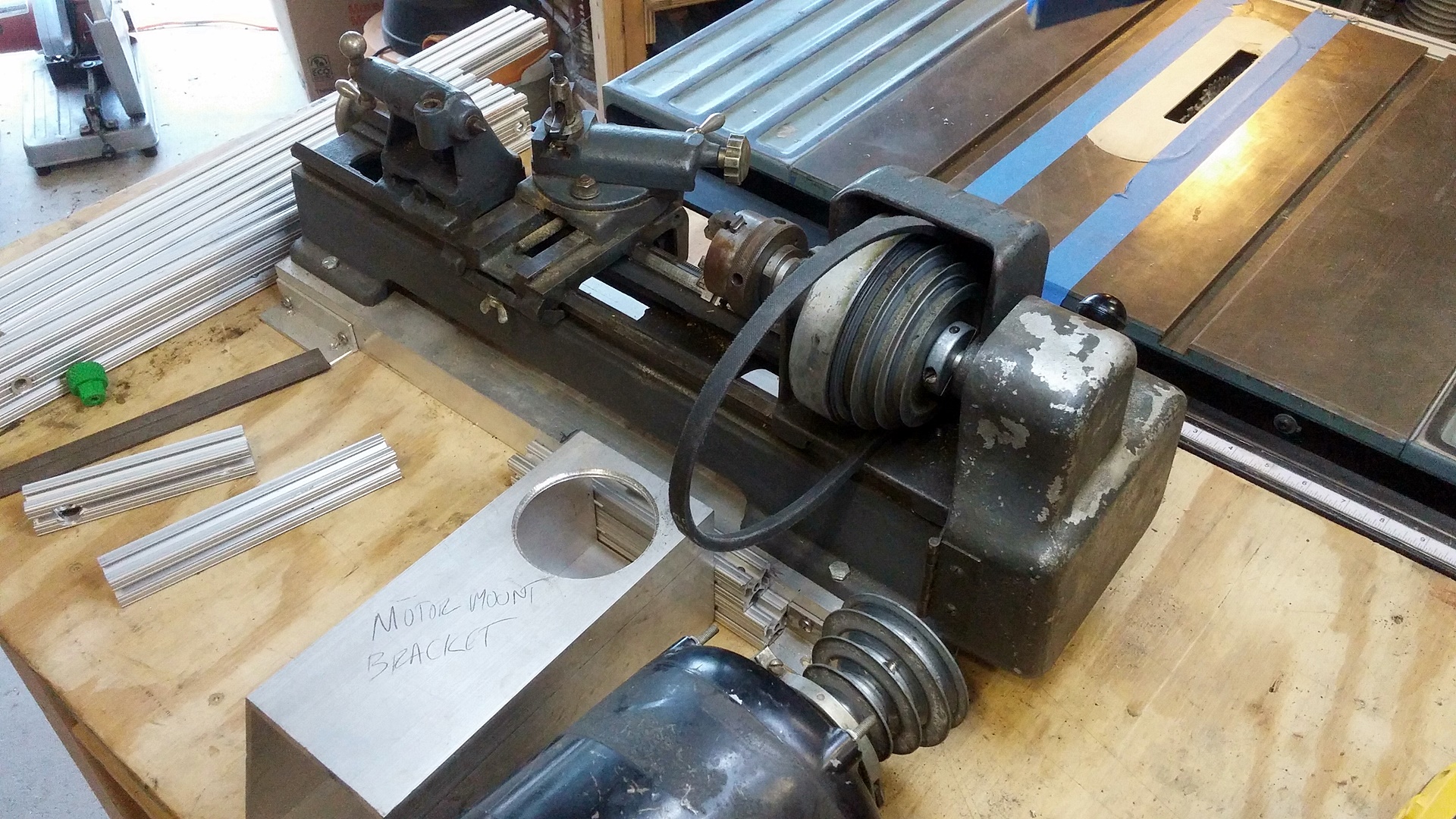

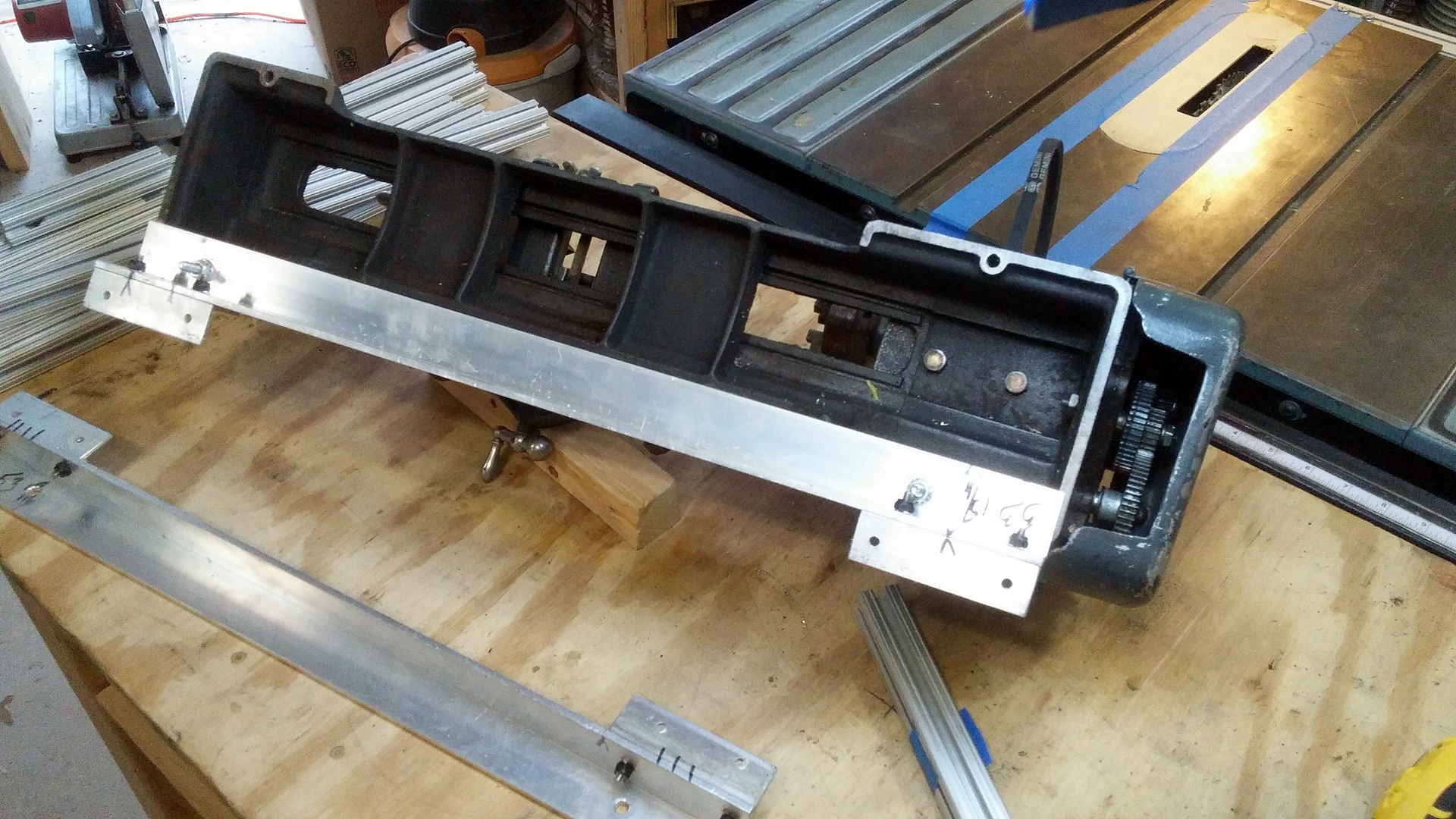

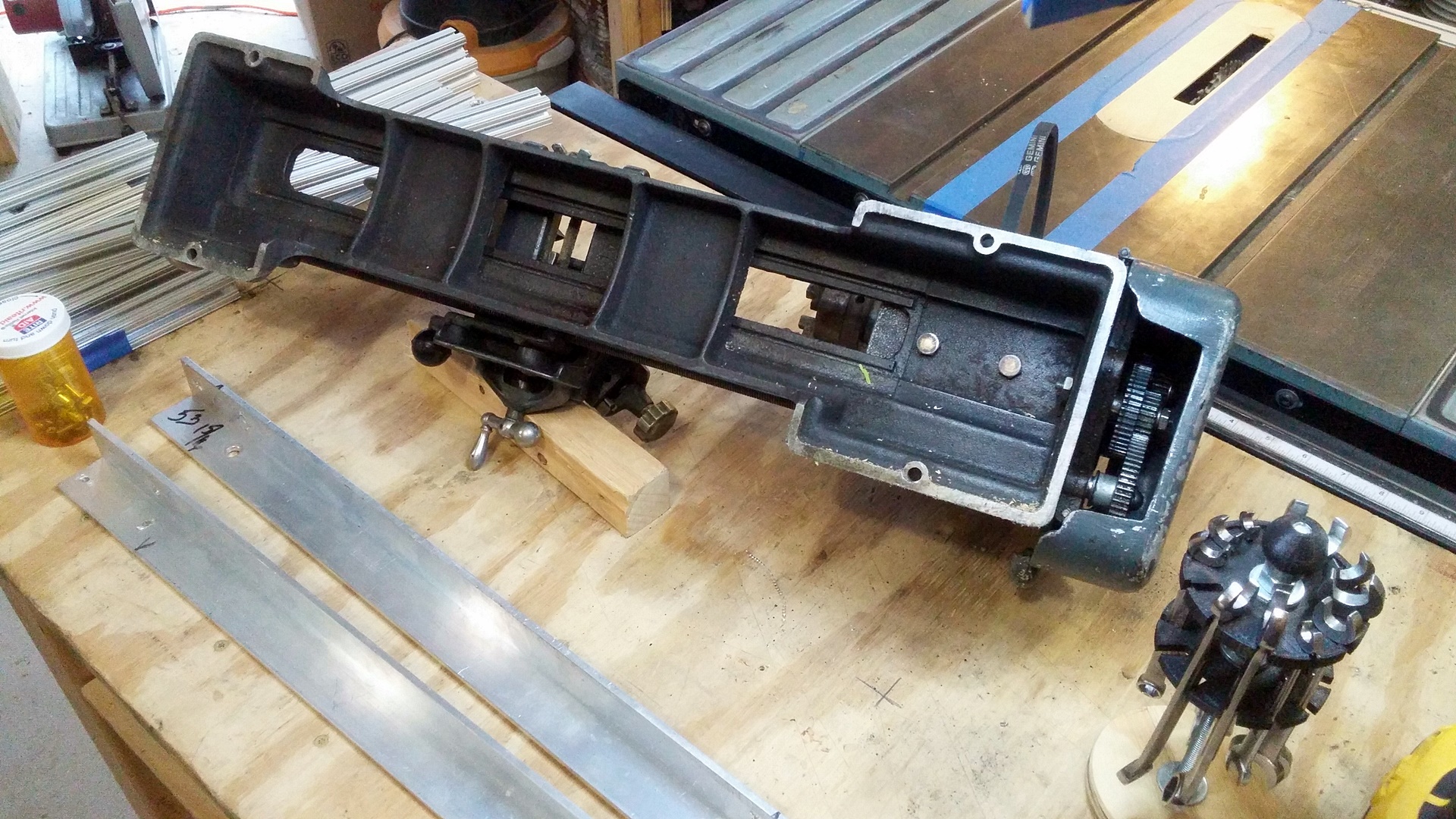

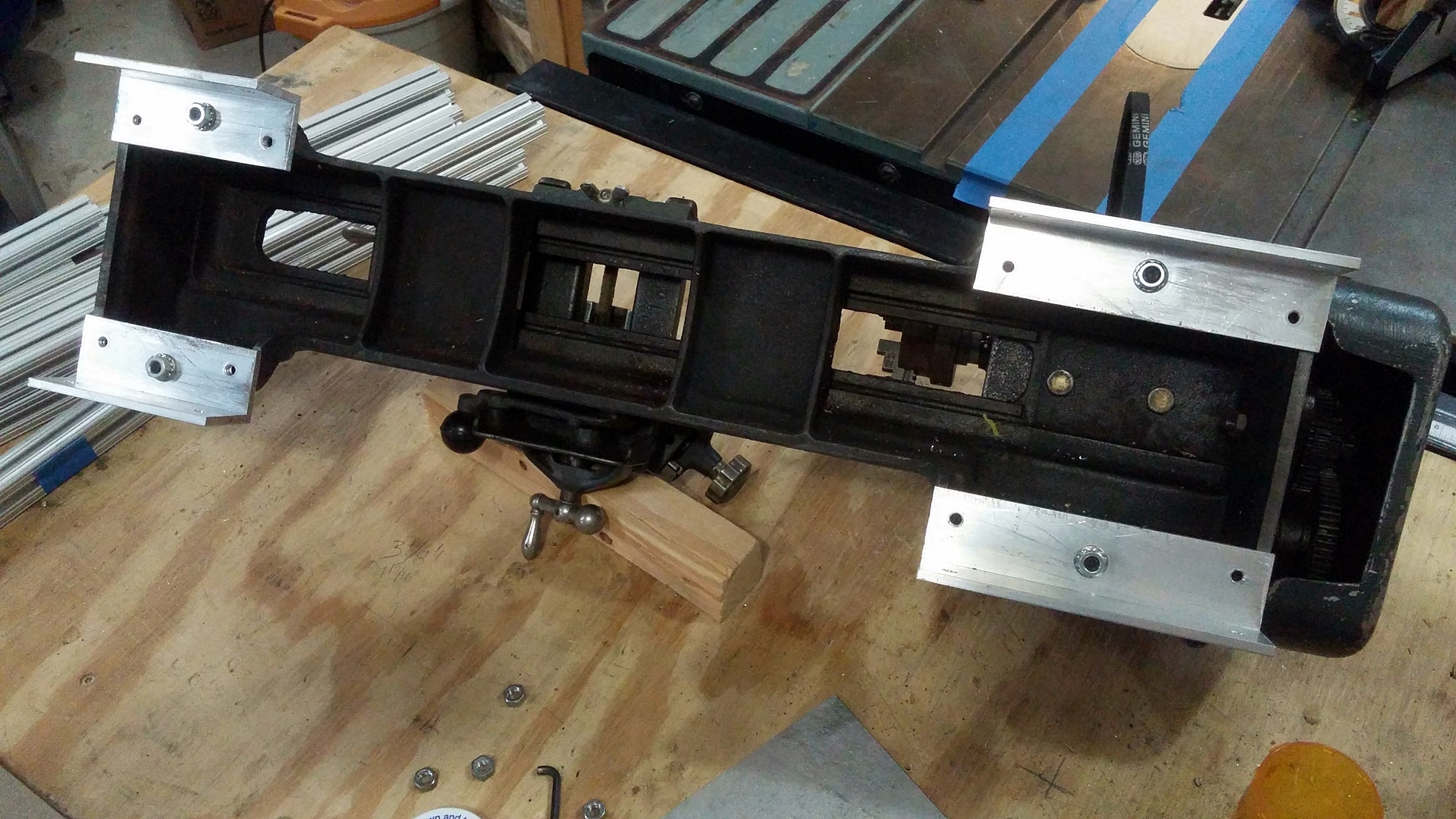

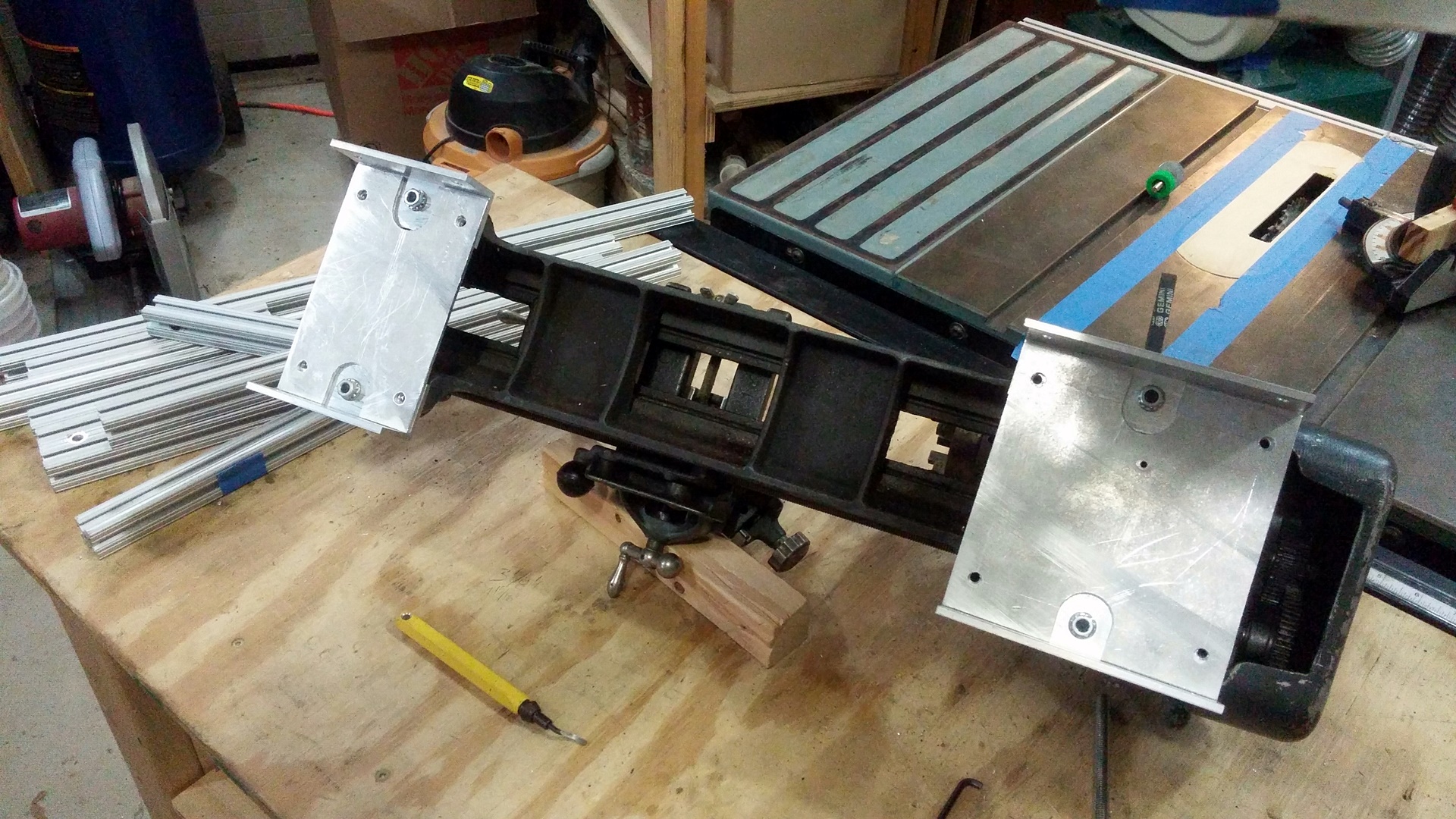

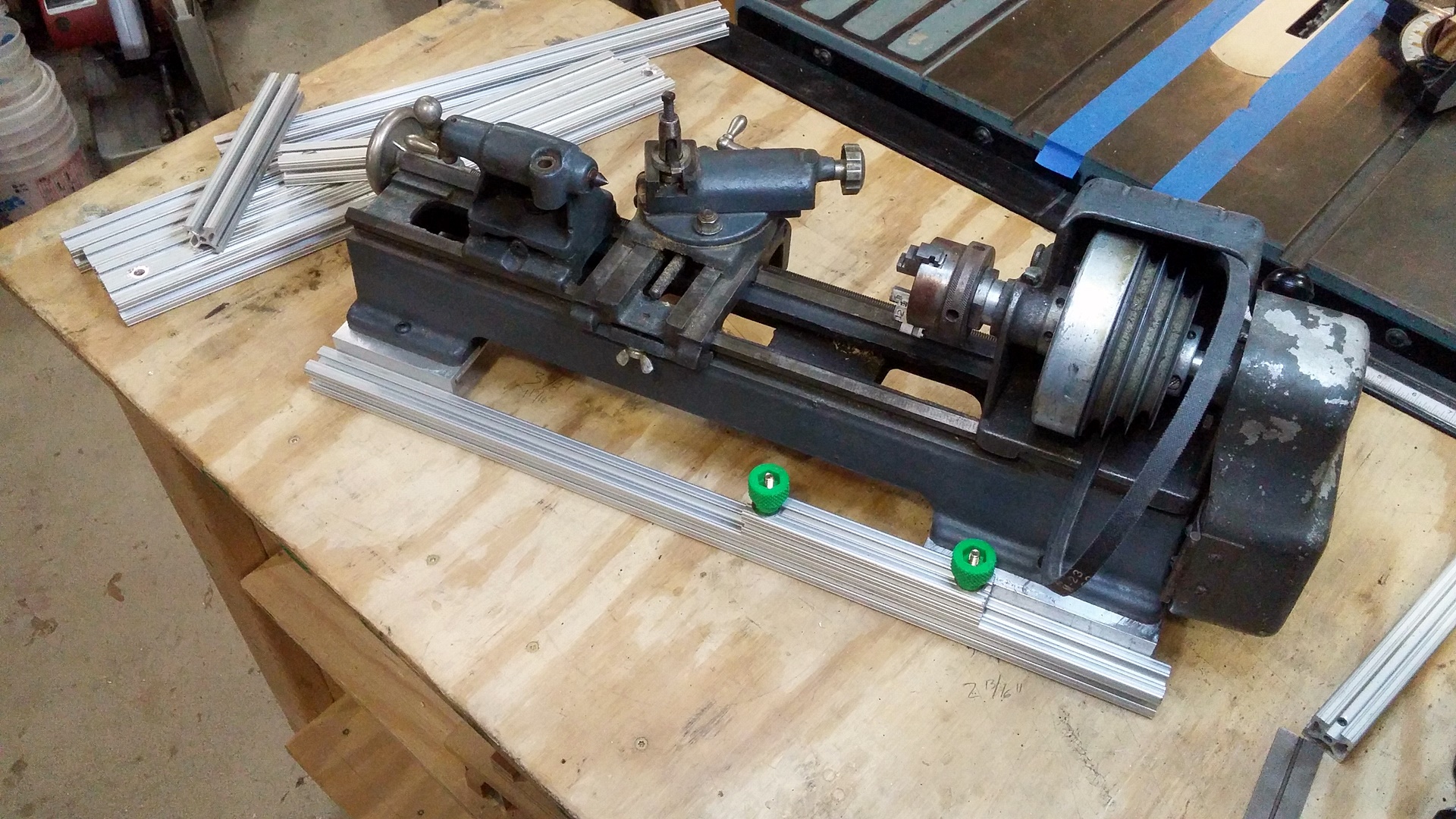

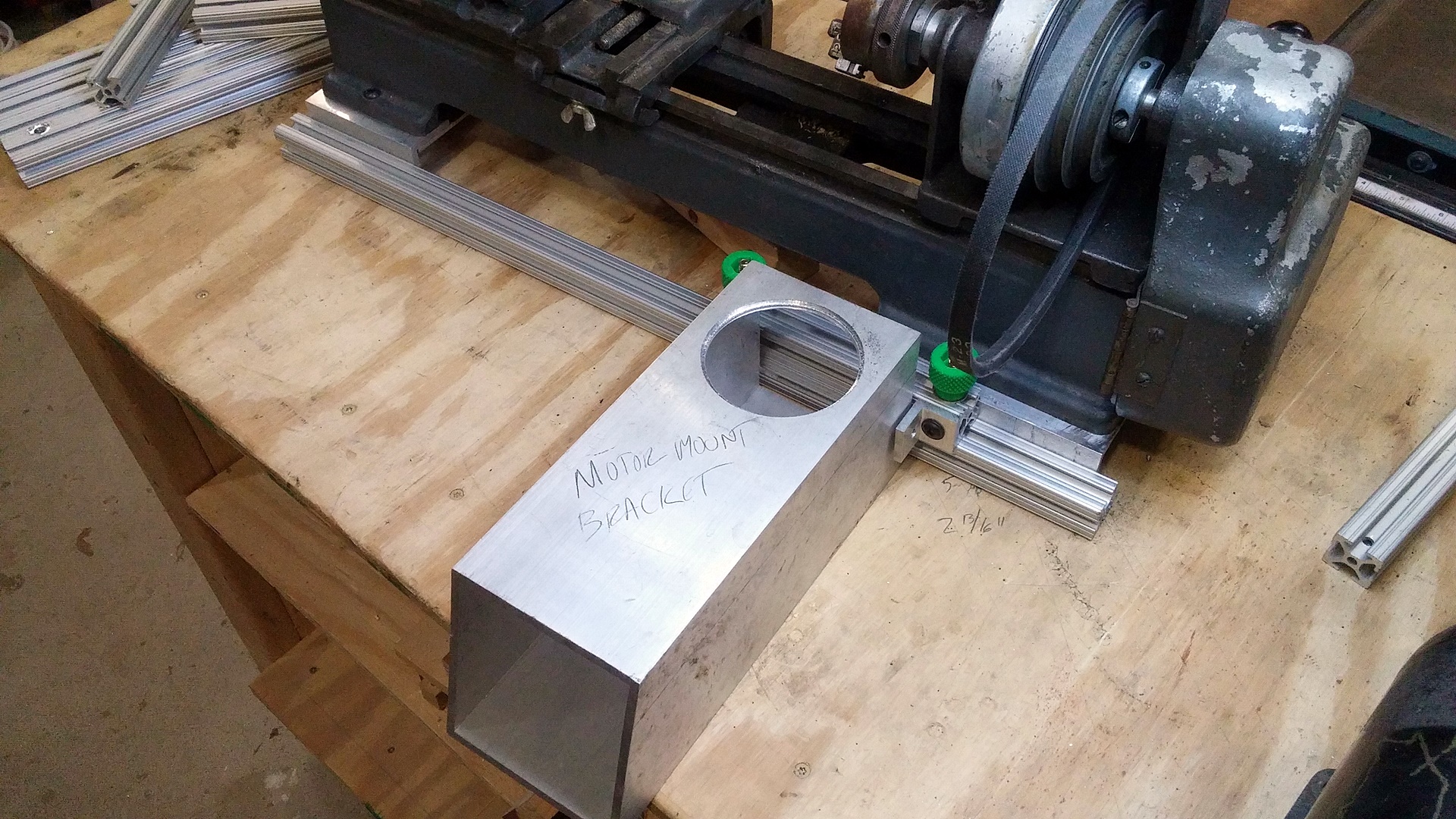

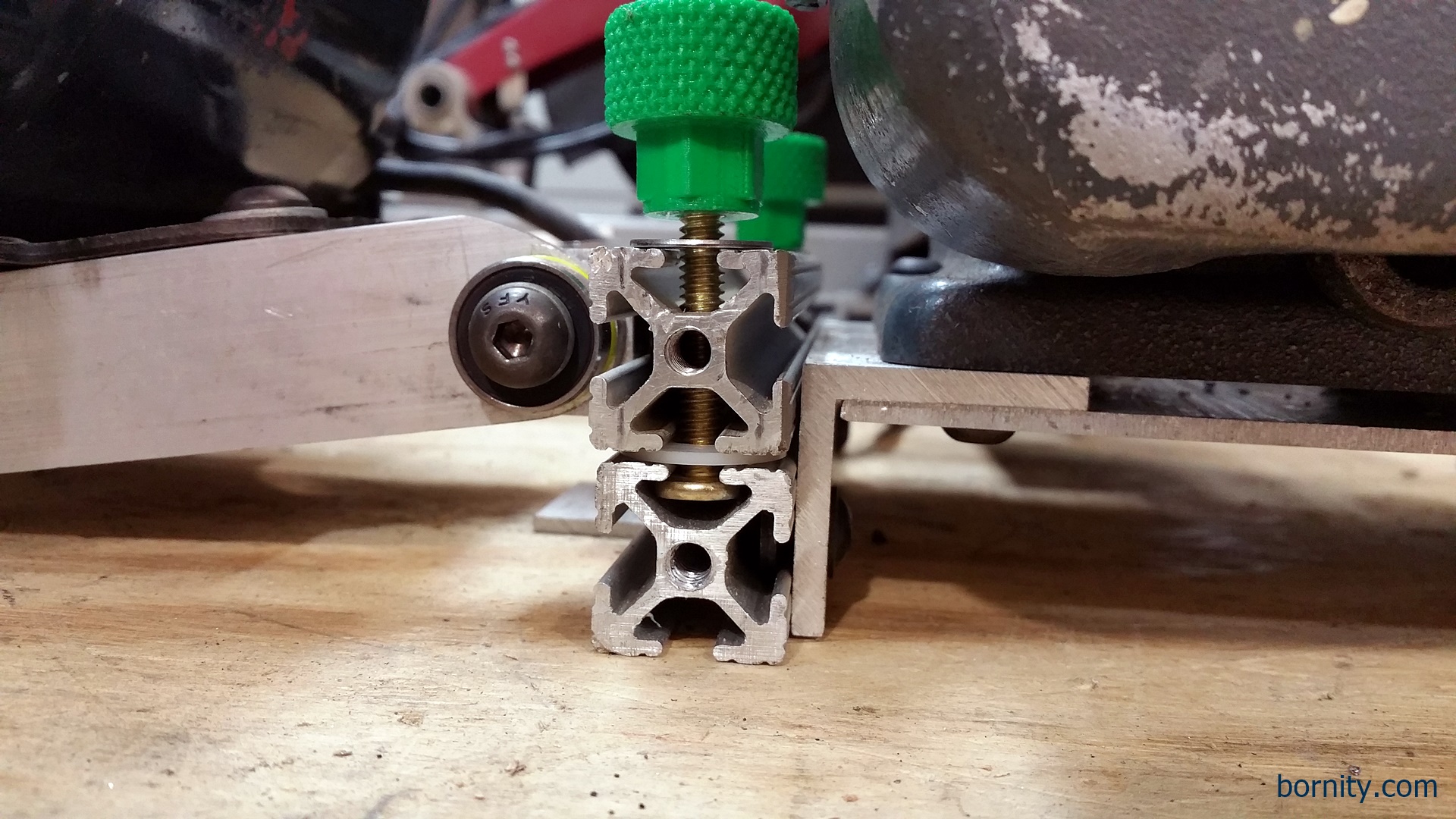

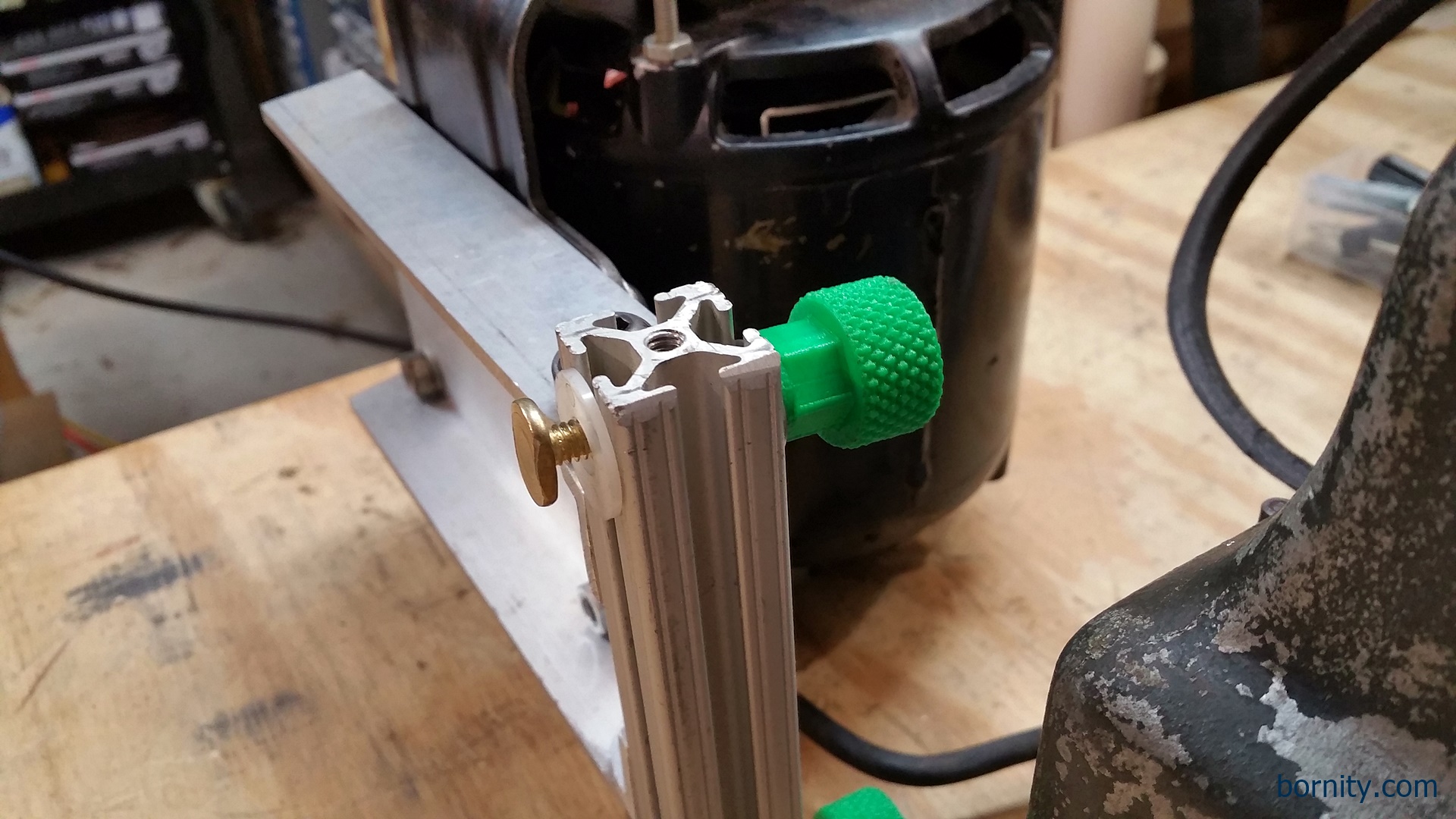

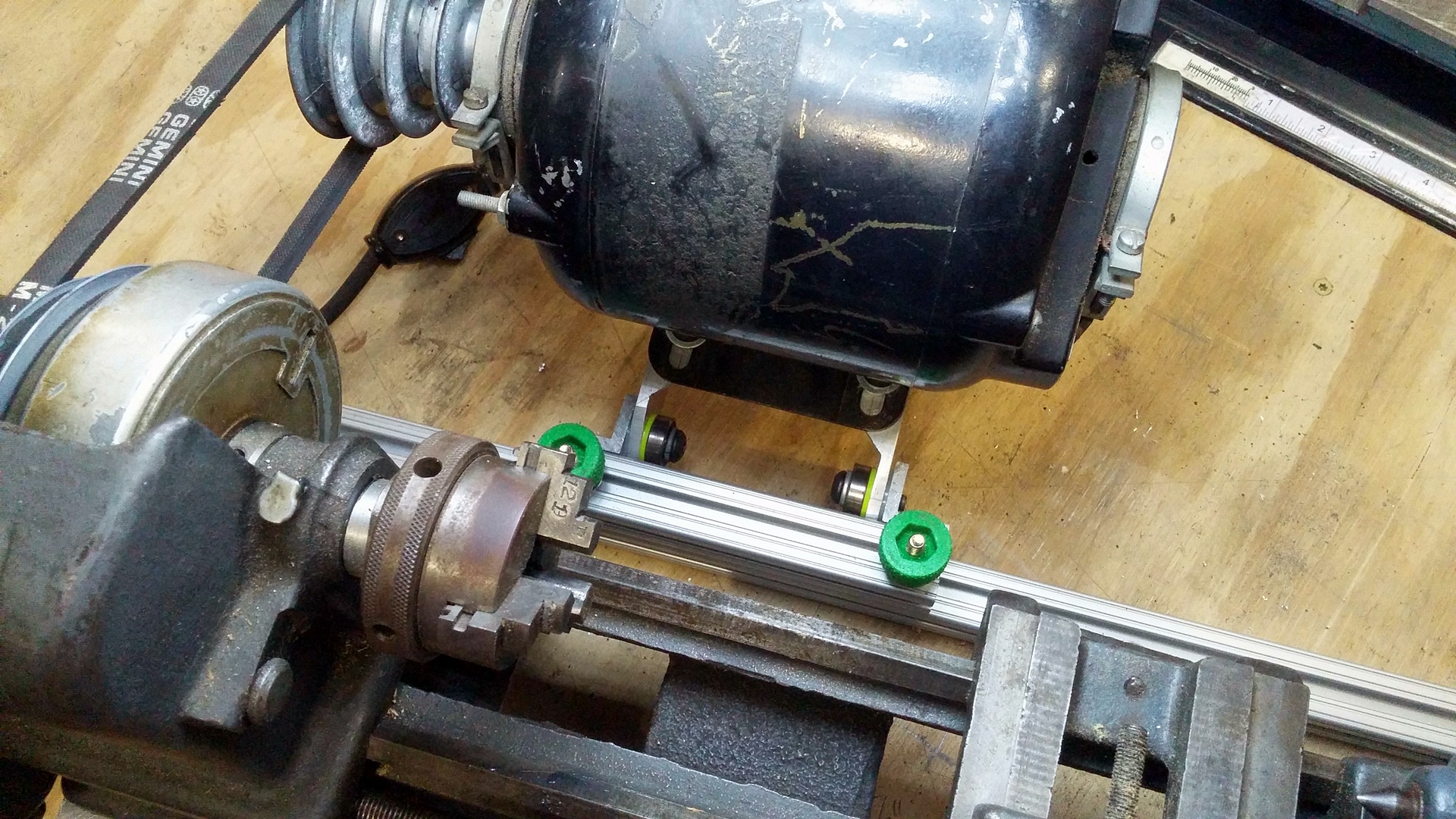

The track frame and brackets are 80/20 & fabricated aluminum. The pivots use my Constant Force Joints and the t-bolts use Ultimate Jig Knobs for the hold downs.

Without the Constant Force Joints, fabrication this mounts becomes much more difficult. I would need to more tightly tolerance holes, buy bronze bearings and buy the specific hardware for the bearing size. Instead, I only have to thread the aluminum bracket and drill pass-through holes in the U-Bracket.

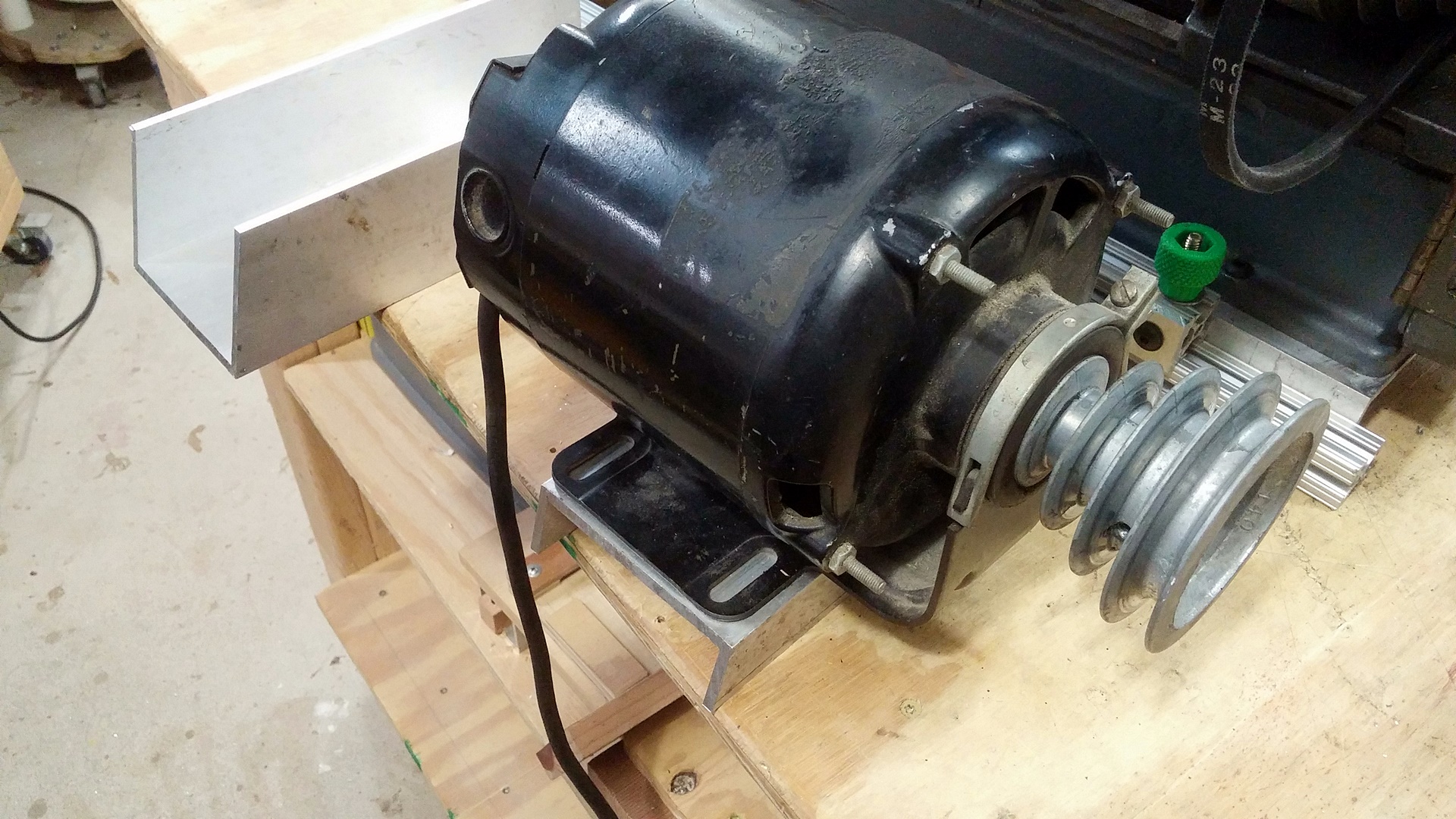

Before I use the machine, I also need rewire the switch to a fixed location the front side. It's very dangerous where it is right now.

If you have any questions, you can find me on Twitter or Reddit.

Enjoy!

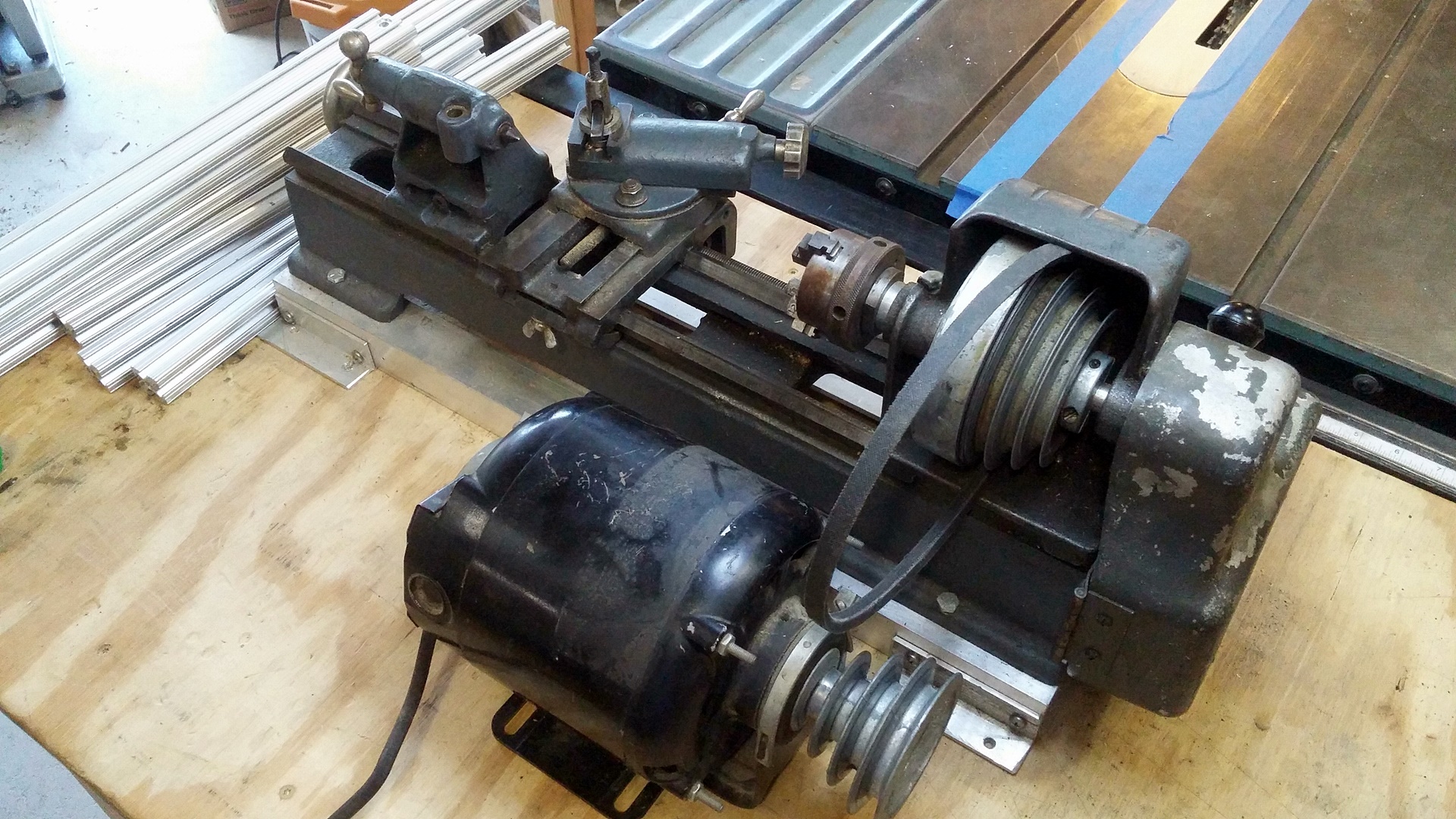

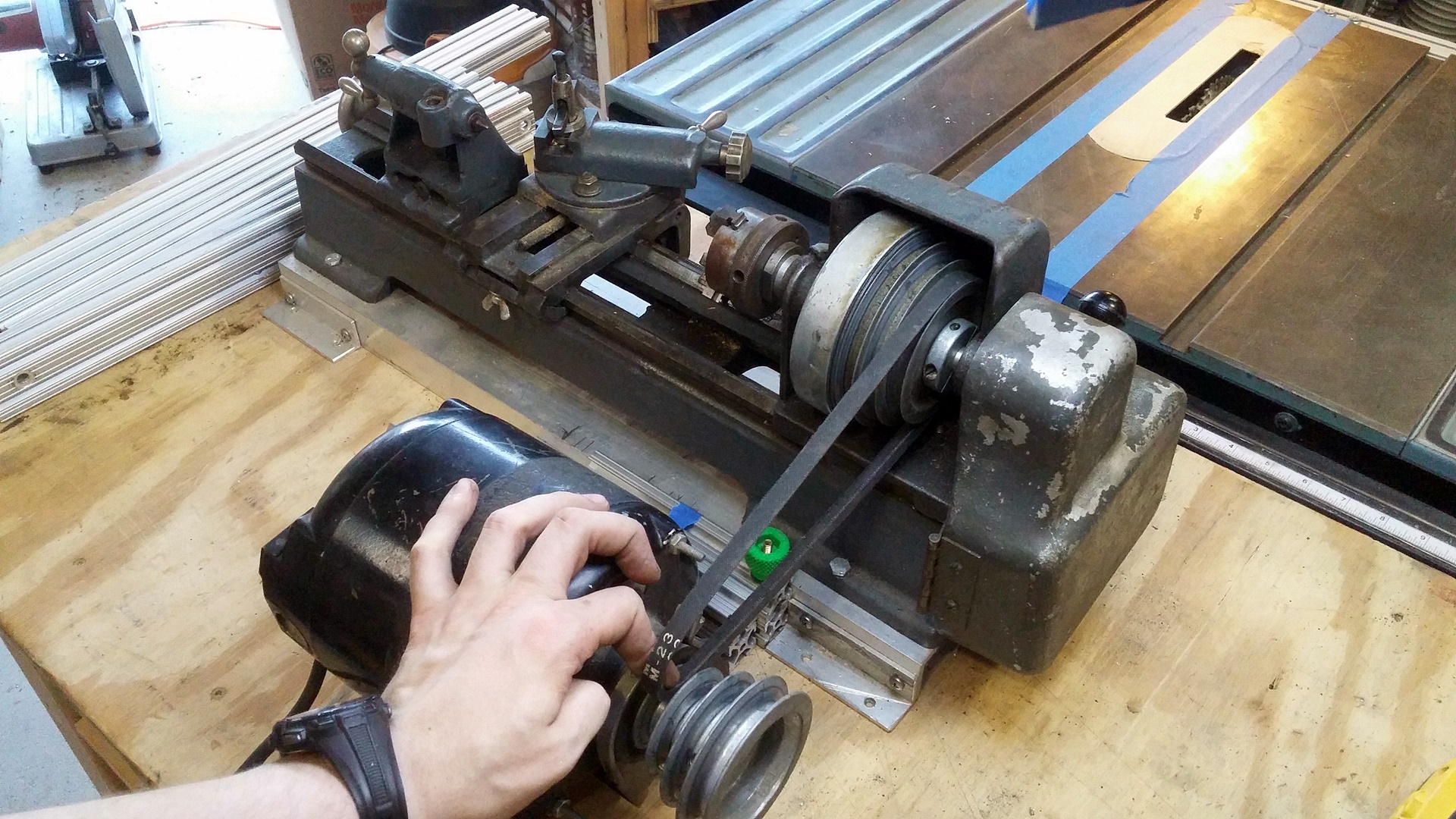

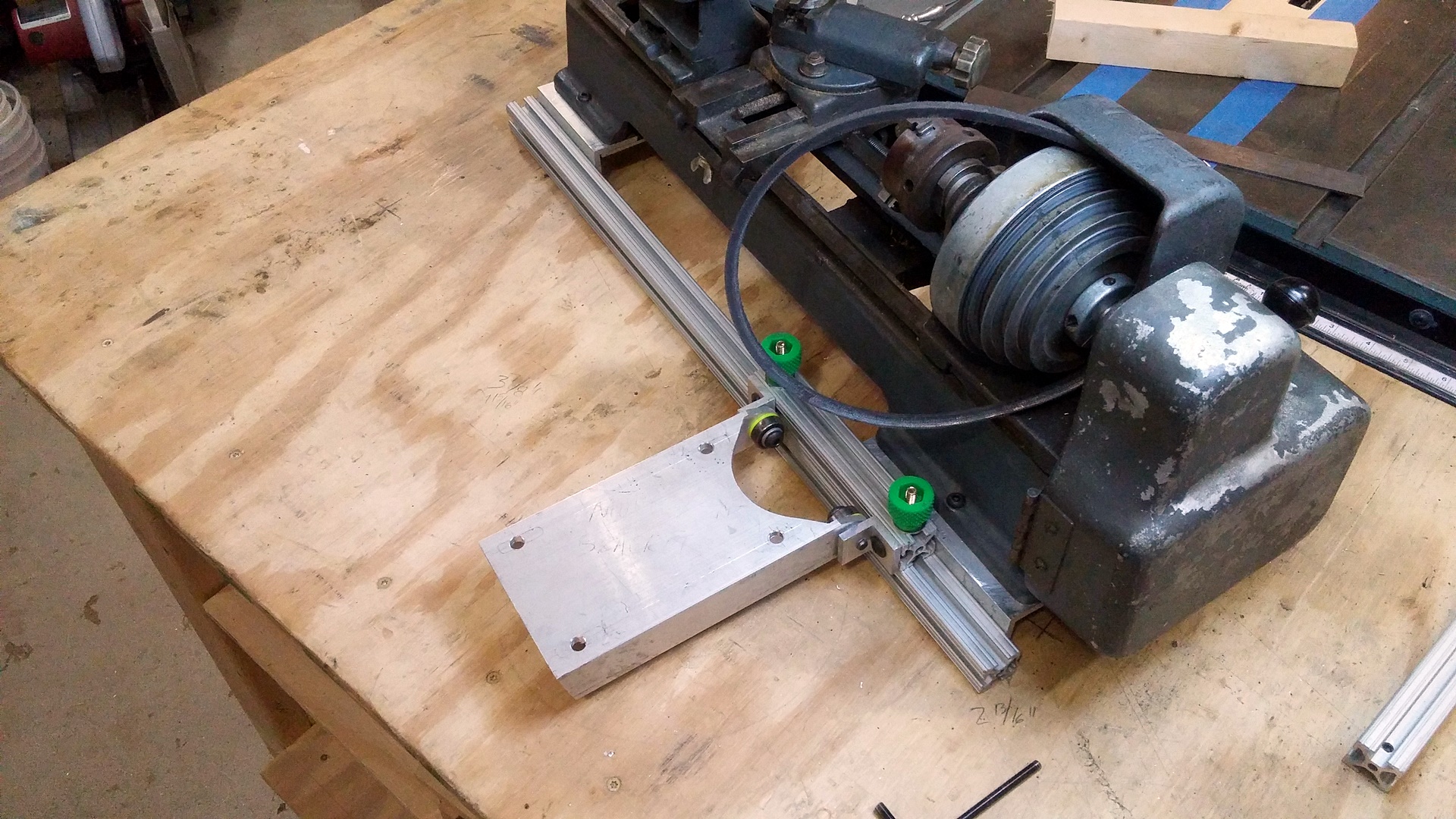

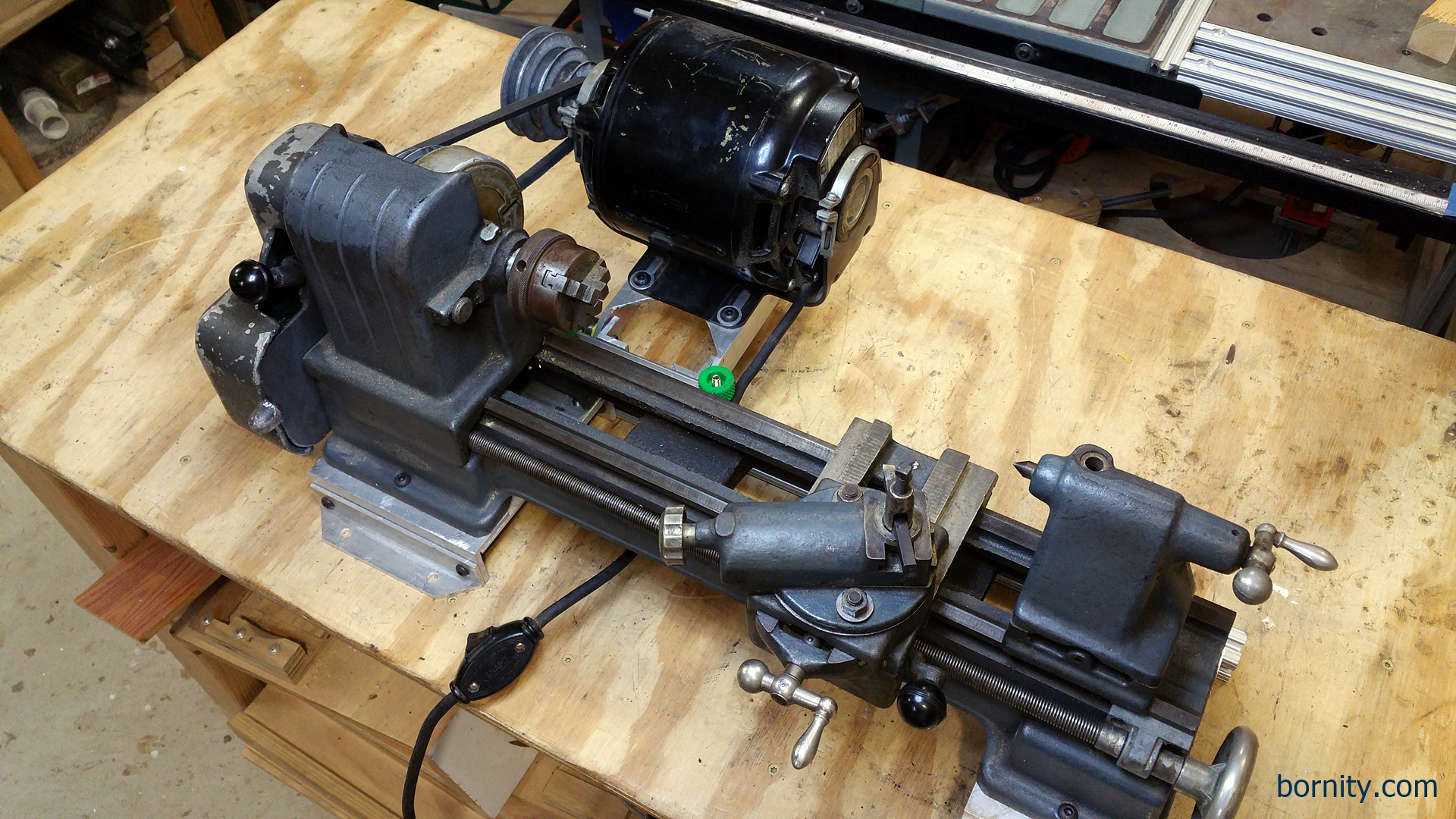

Completed Motor Mount

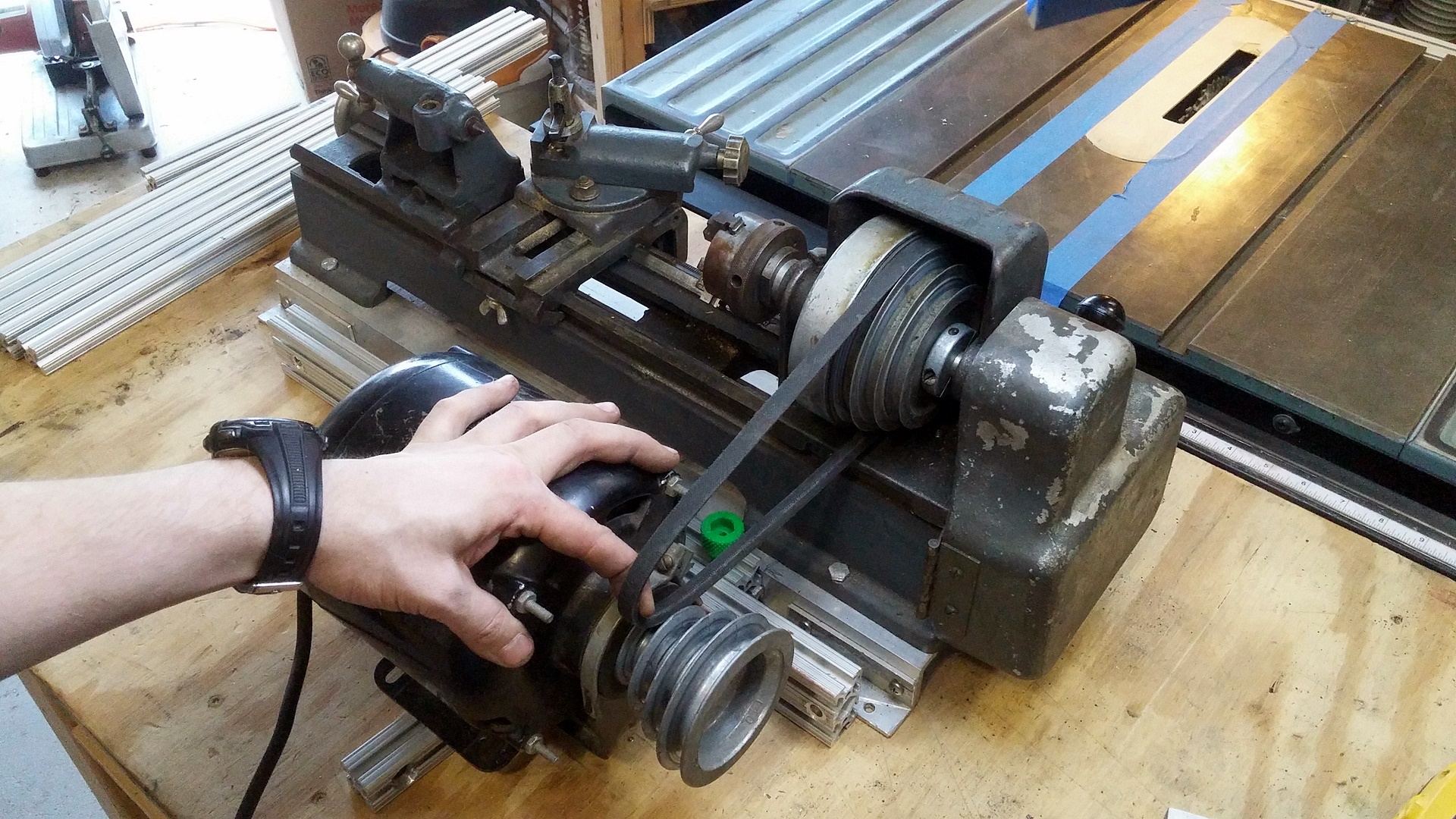

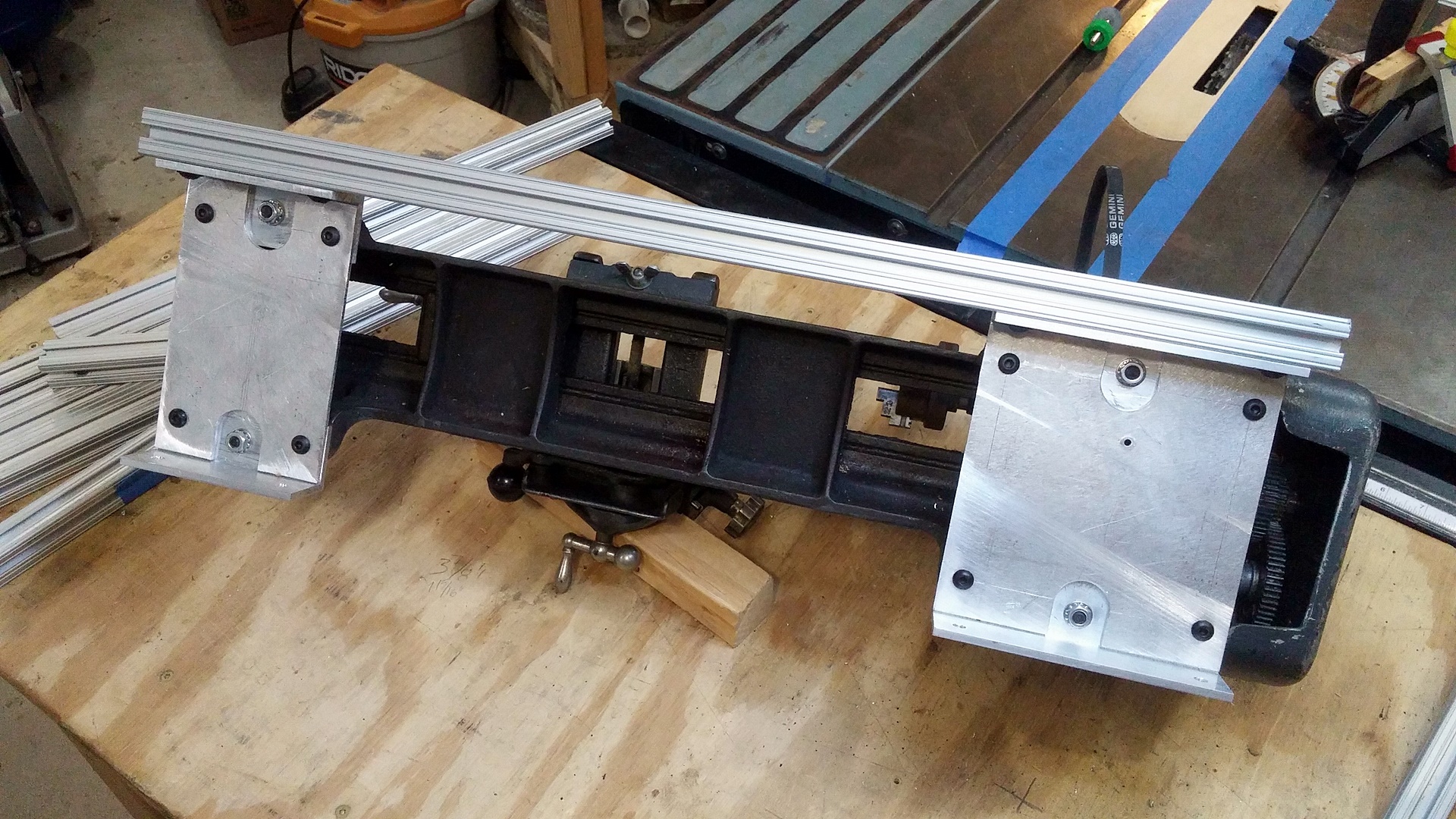

Tilt the motor, loosen the knobs, slide, align the pulleys, tighten the knobs, release the motor.

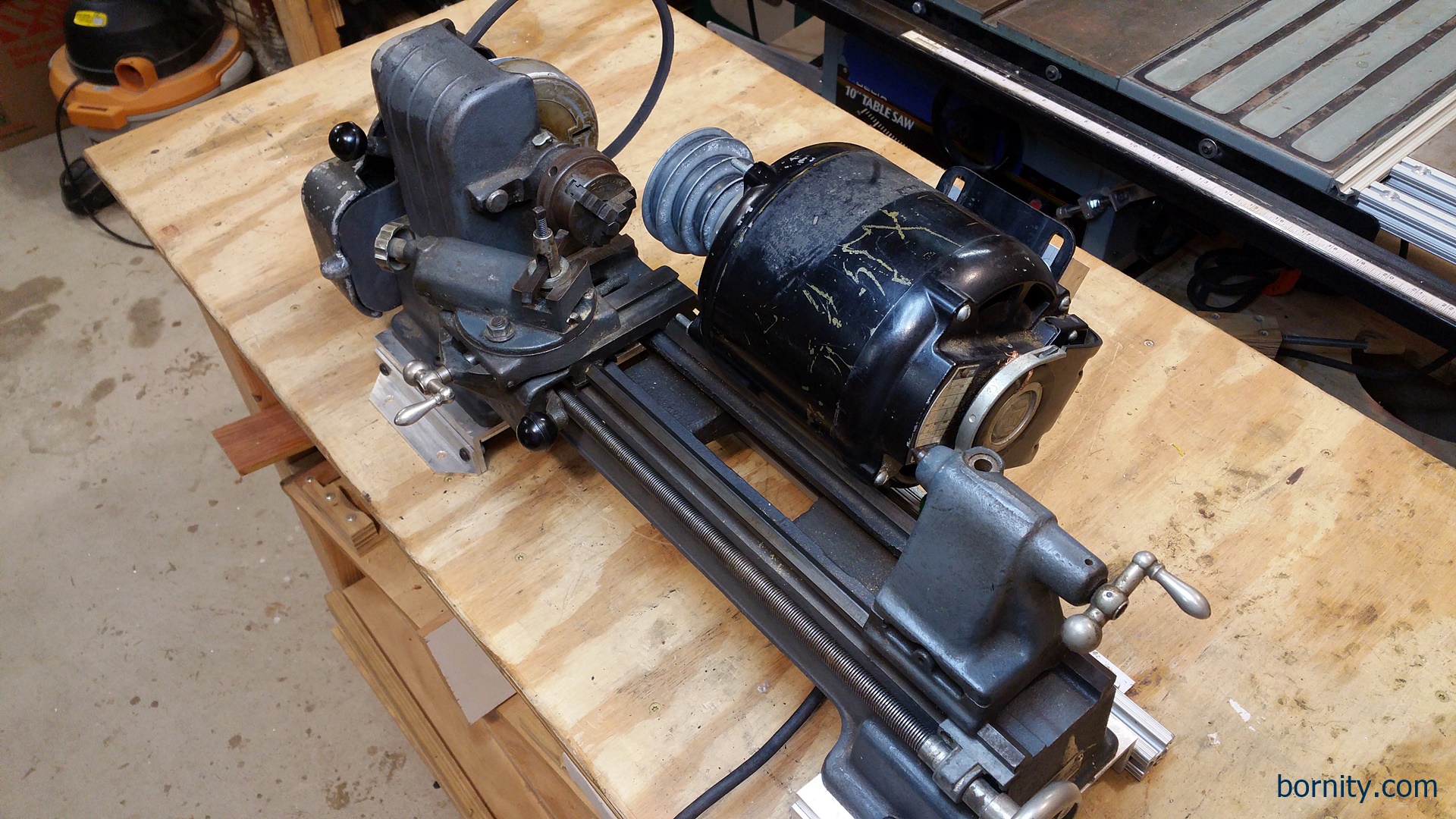

NOTE: This switch/wire placement is VERY DANGEROUS. This was only for demonstration purposes of the motor adjustment. The switch should be fixed on the front of the machine with no loose wires. Before I actually use the machine, I will complete the wiring, and post an update.

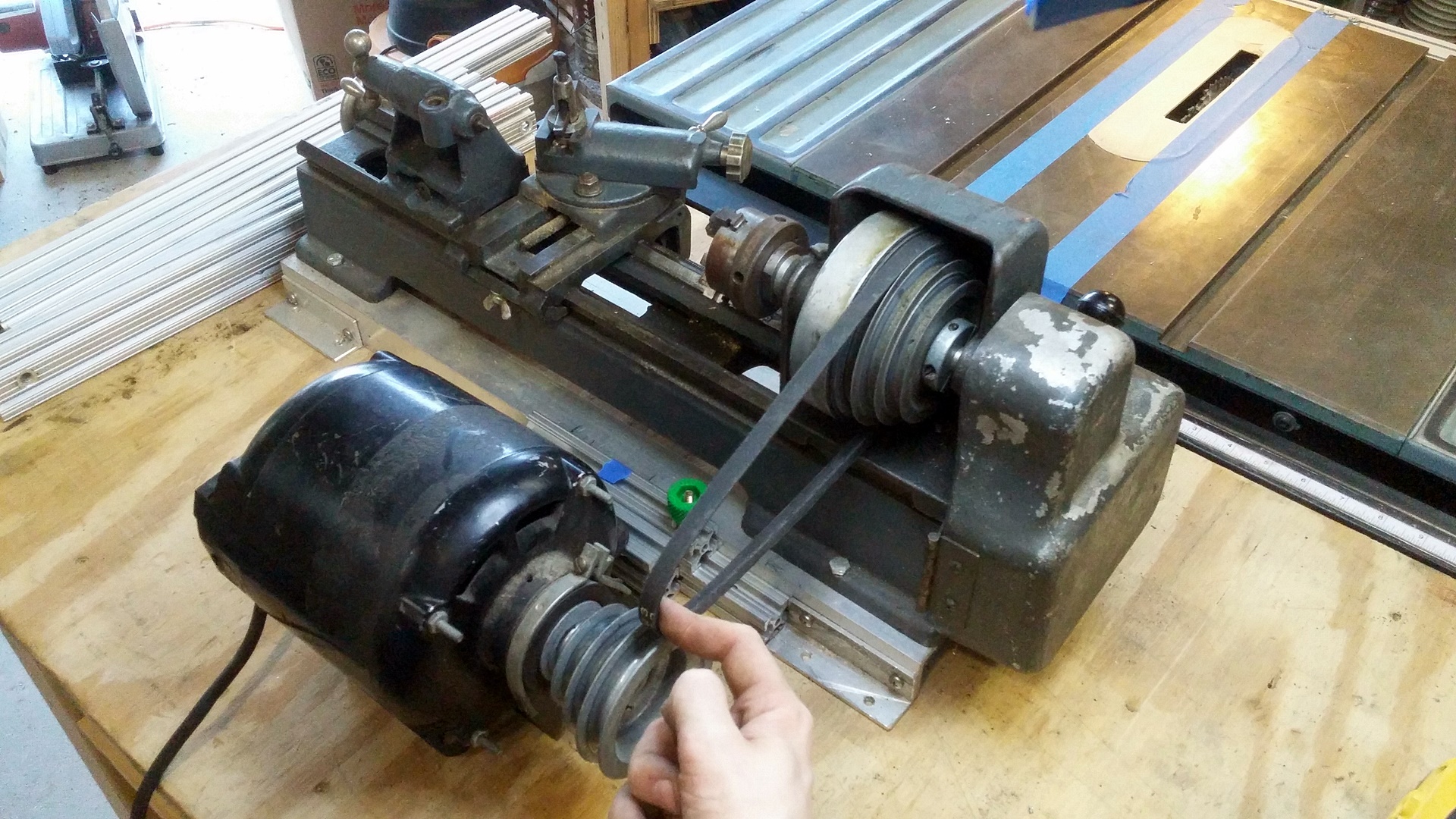

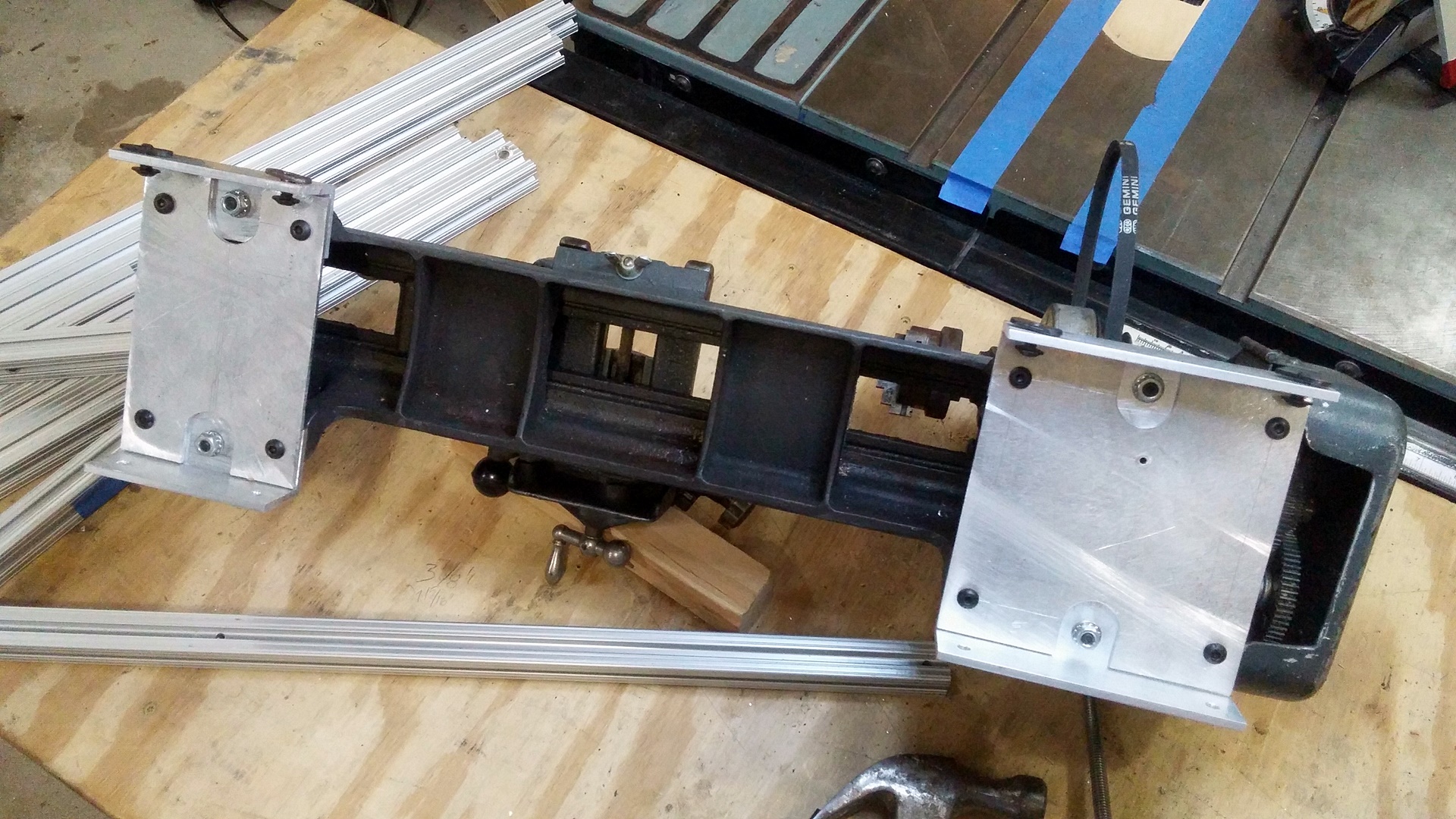

Rear View of movement. For demonstration purposes only.

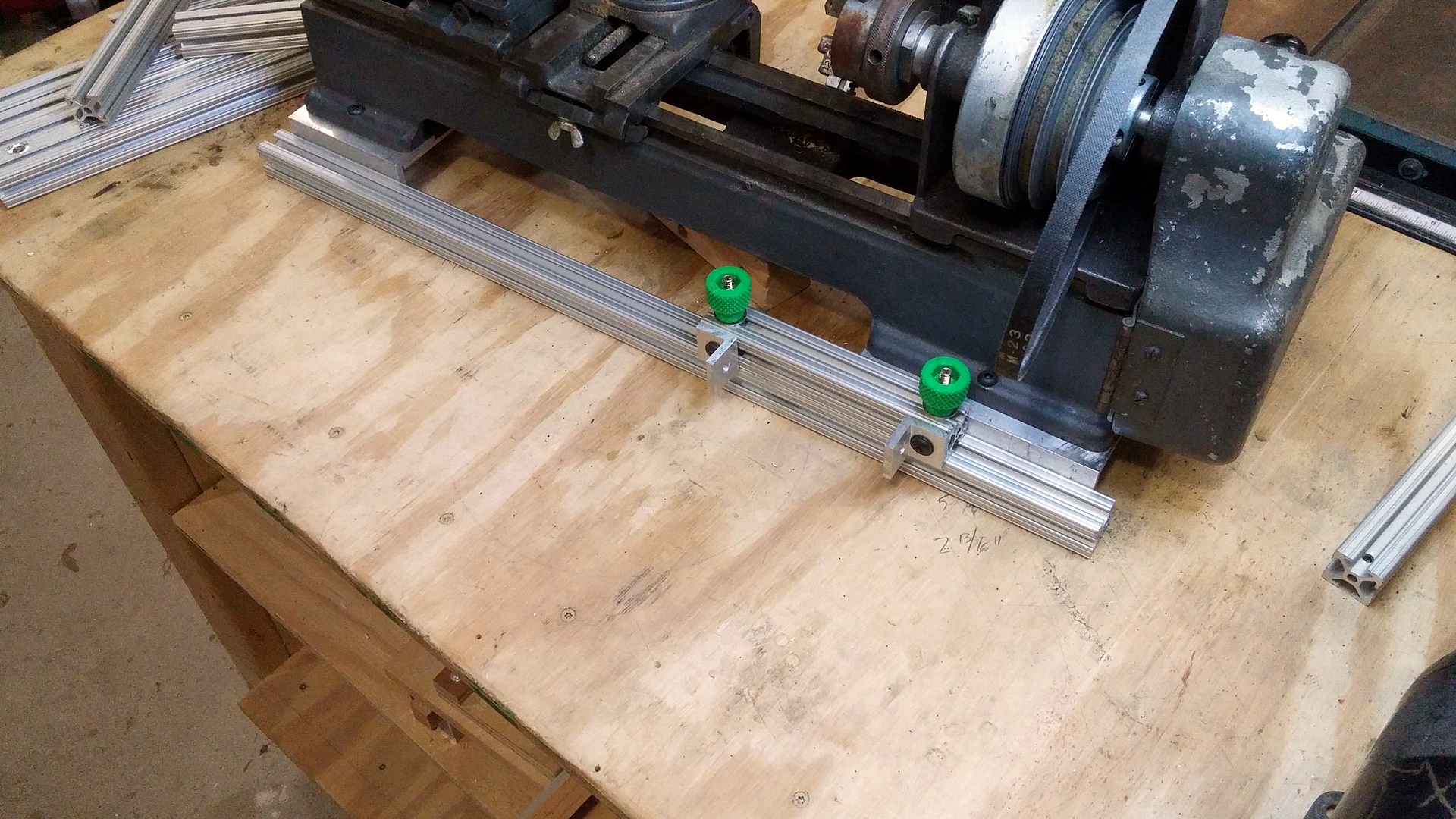

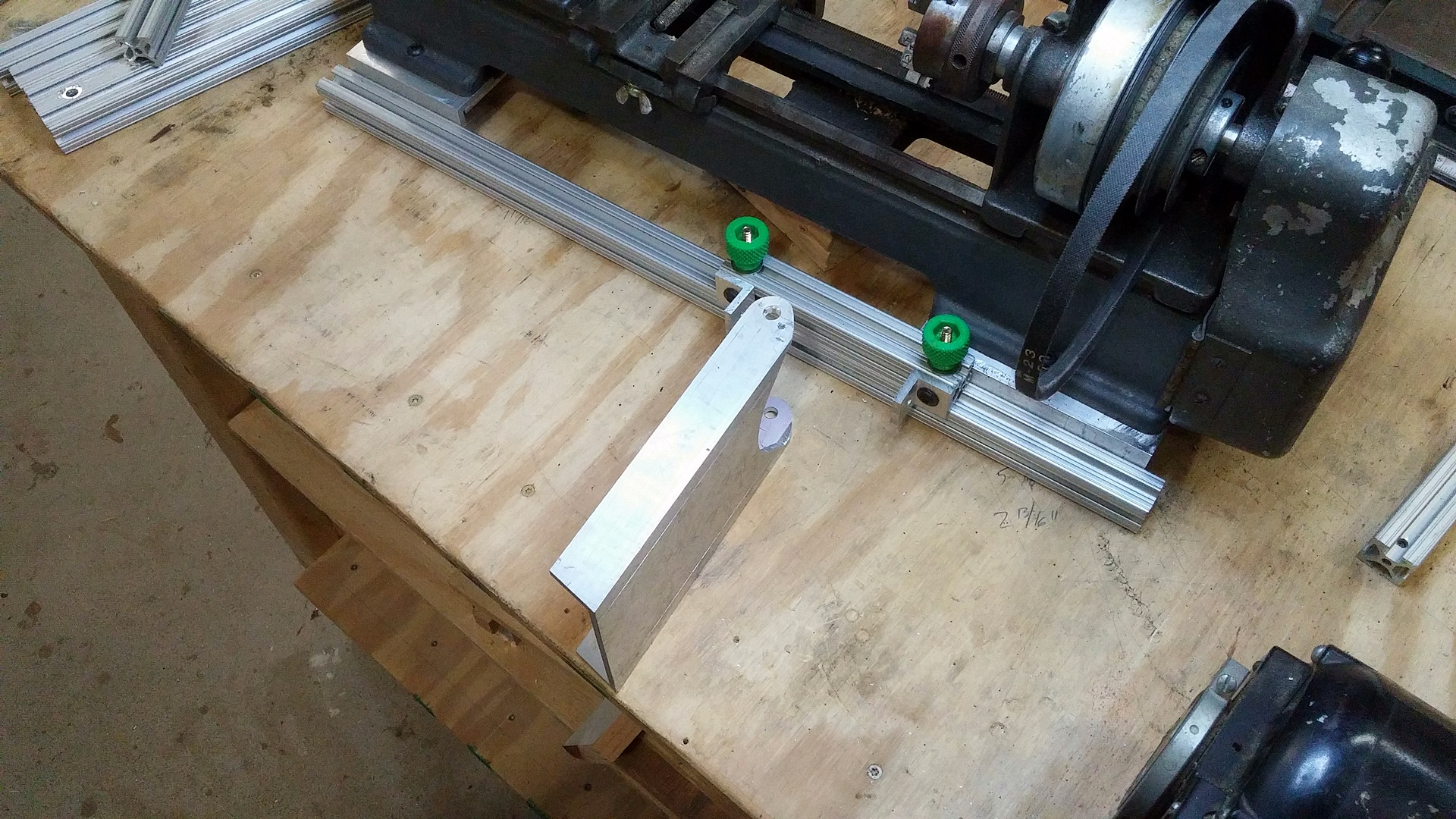

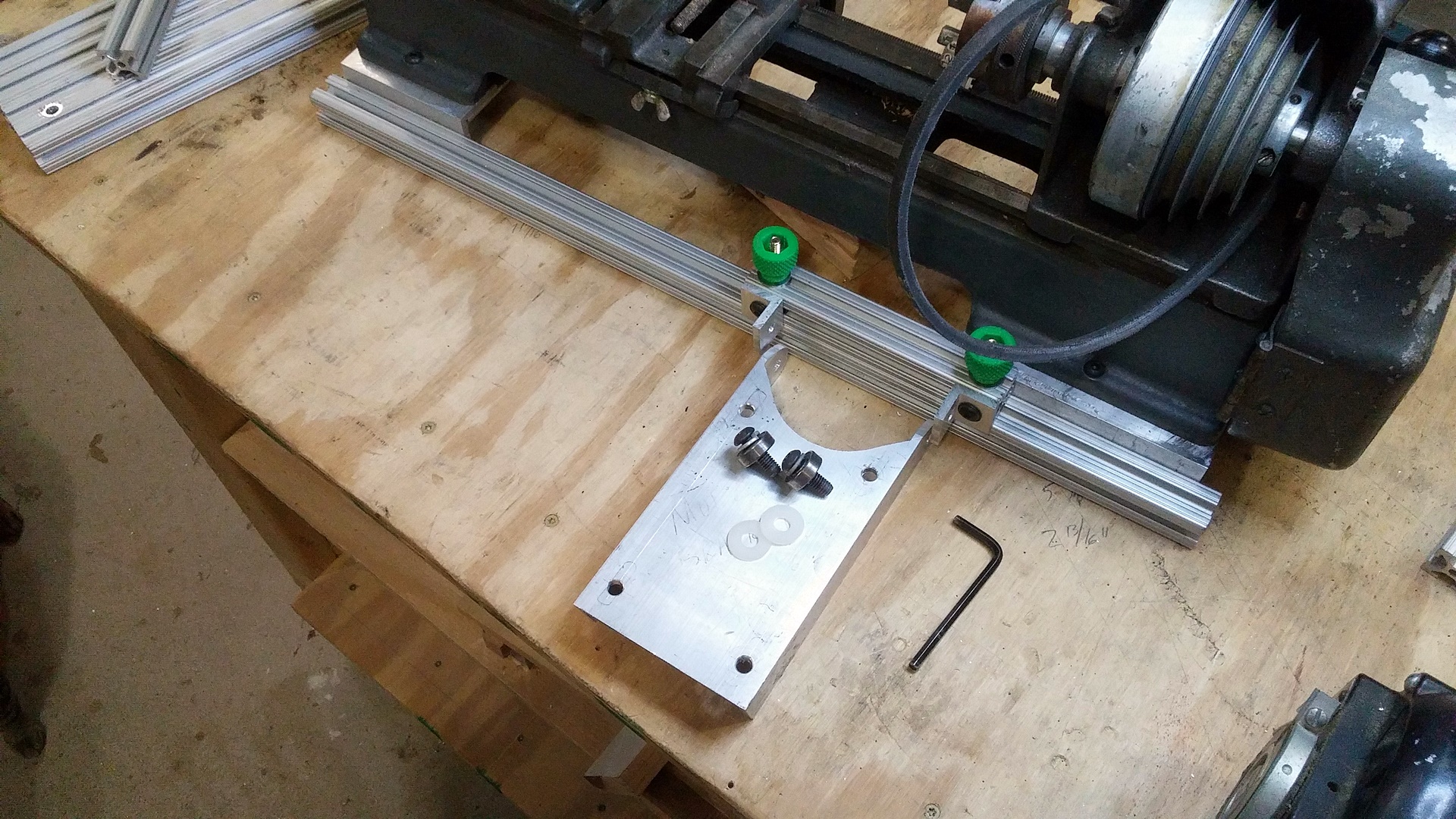

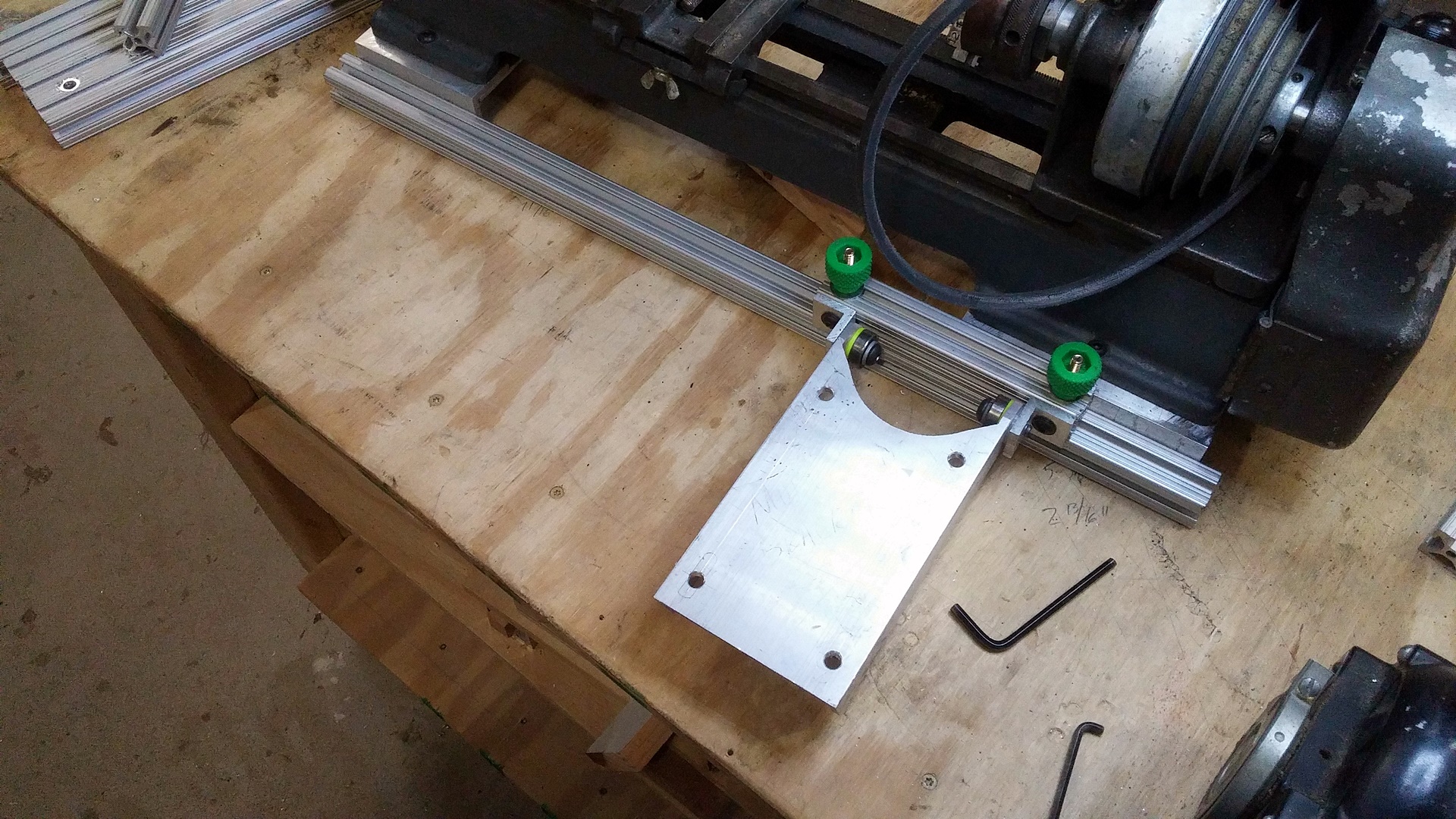

Basics of how the slide functions.

Related Pages:

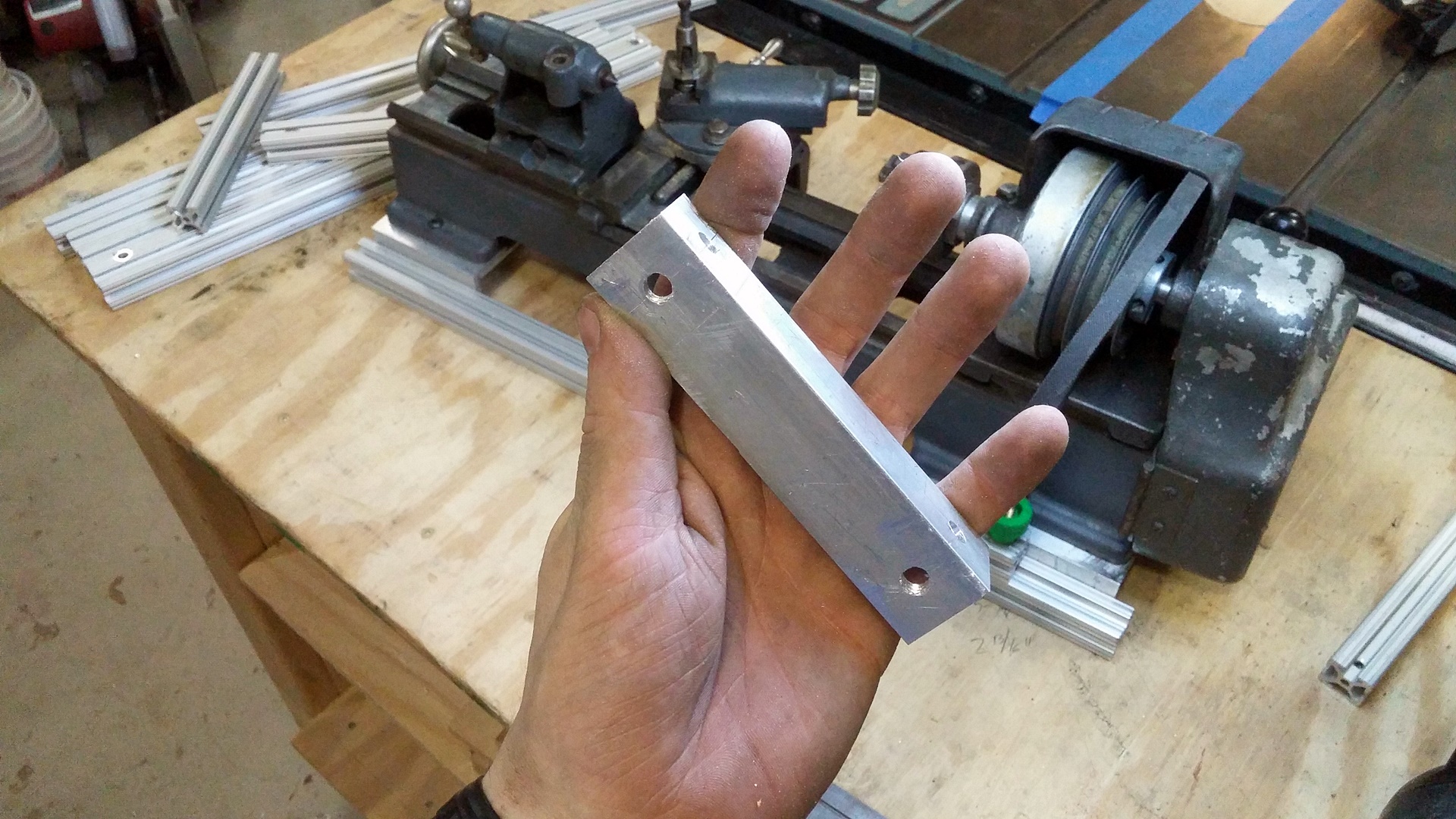

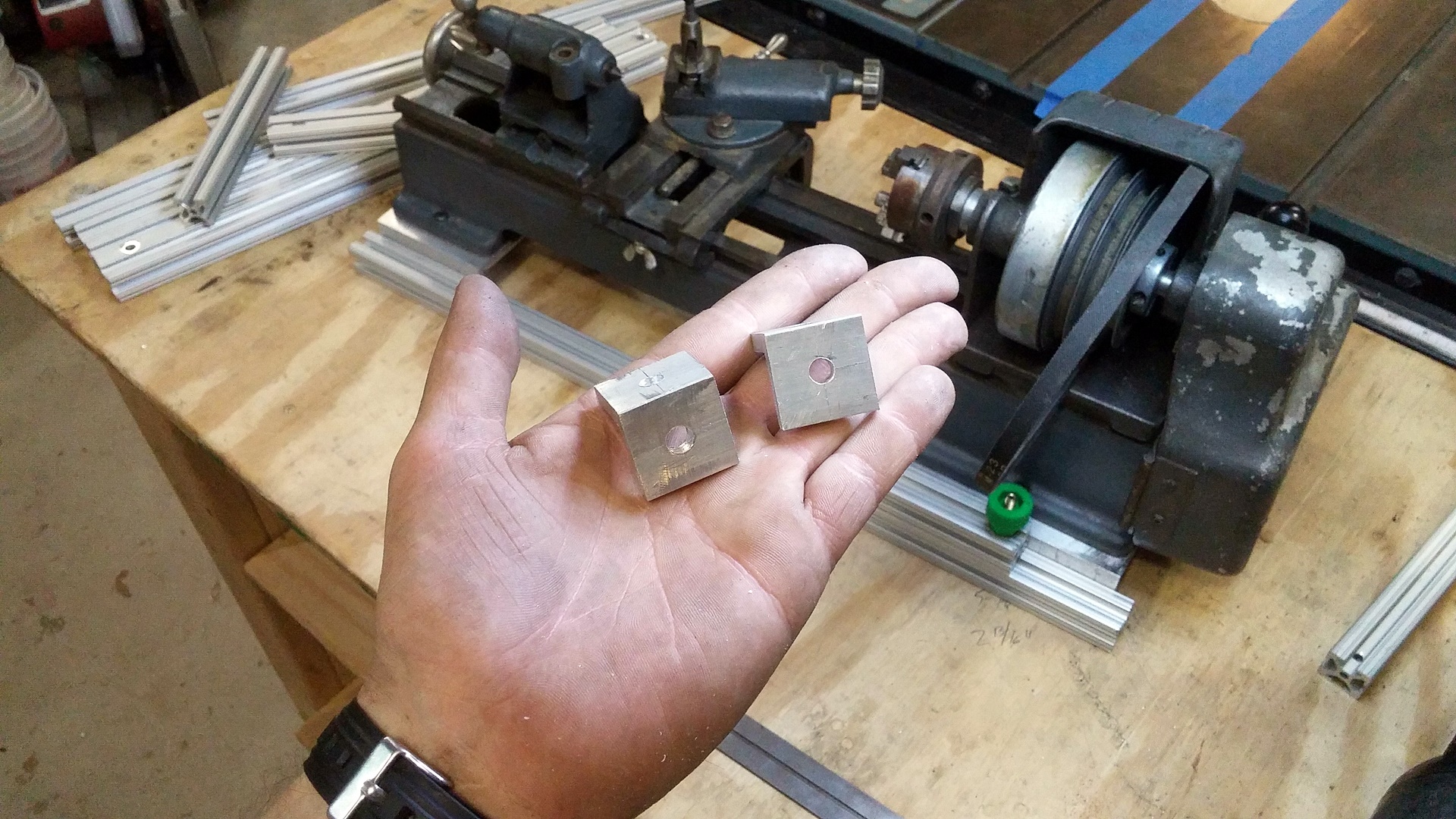

Build Photos

Bonus Cat!

Apollo explores the garage.

Thanks for stopping by!